Plastic pallets can be recycled. In many industrial supply chains, they are one of the easiest load carriers to recover—when the resin type and design match your local recycling channel.

Still, most procurement teams hesitate for practical reasons. Will a recycler accept this pallet? Is it HDPE or PP? Will rubber pads or mixed parts cause rejection? Can the pallet still meet racking, hygiene, and export needs? This article answers those questions in a direct way, so your next decision is easier to defend on cost, compliance, and ESG reporting.

Quick Answer—Are Plastic Pallets Actually Recyclable?

Plastic pallets are recyclable in many regions, but recyclability is not automatic. It depends on the pallet material and what local recyclers can process.

What “Recyclable” Means in Real Supply Chains

In real operations, “recyclable” means your retired pallets can be collected and reprocessed by an industrial recycler. If no recycler accepts that resin type, the pallet will not be recycled in practice.

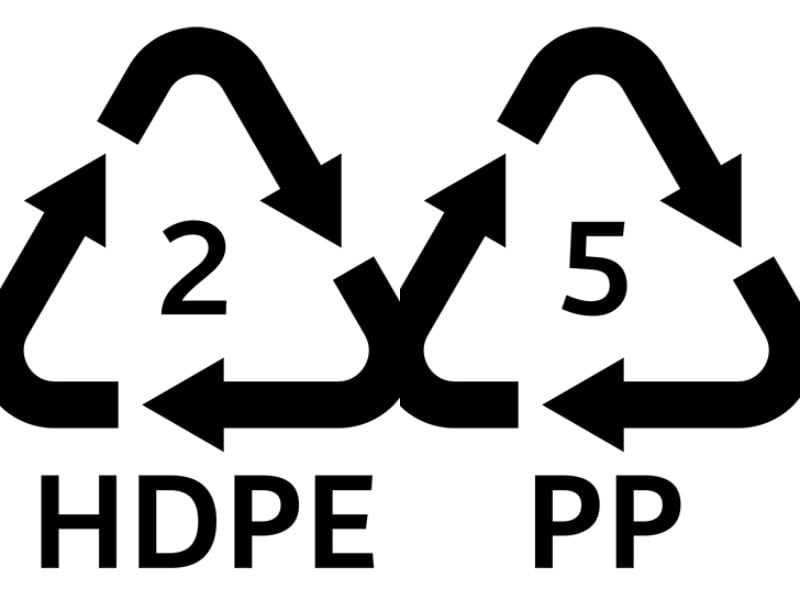

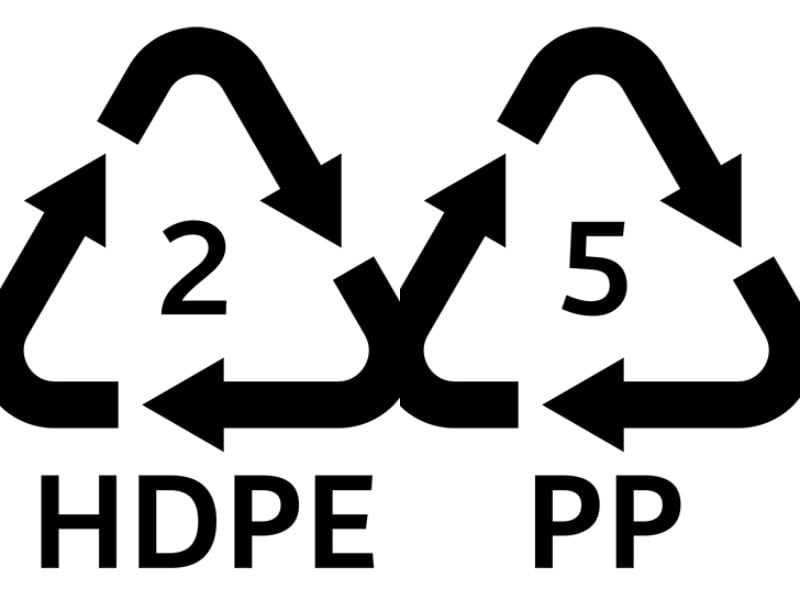

A common question is: what does the recycling triangle code mean? It shows the resin category (RIC). For pallets, you will often see #2 or #5. The code helps sorting, but it does not guarantee acceptance.

Most plastic pallets are made from HDPE (RIC #2) or PP (RIC #5). These materials are durable and widely used in logistics, so recycling routes are often available.

Which Plastics Can Be Recycled (And Which Often Cannot)?

If your goal is a predictable recycling outcome, material choice comes first. The wrong resin can lead to rejected loads and higher disposal costs.

Plastics That Are Commonly Recyclable for Industrial Pallets

Most industrial recyclers prefer pallets made from:

HDPE (RIC #2)

PP (RIC #5)

These pallets are usually accepted because the plastic is thick, consistent, and valuable. Recycling is smoother when pallets are clean and single-material.

Another common question is: which is easier to recycle, HDPE or PP? In many markets, HDPE is the safest choice because acceptance is very common. PP is also recyclable, but acceptance can vary more by region.

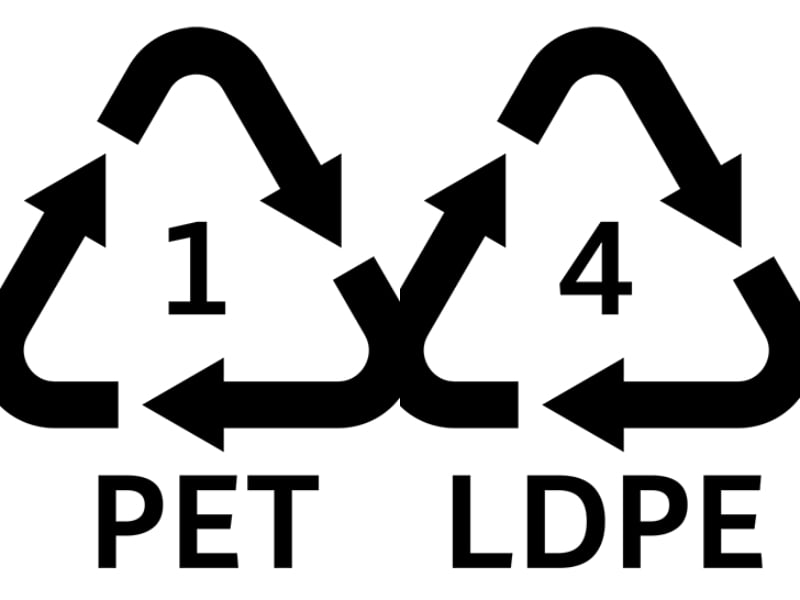

Plastics That May Be Recyclable but Need Confirmation

Some plastics can be recycled, but acceptance is less stable:

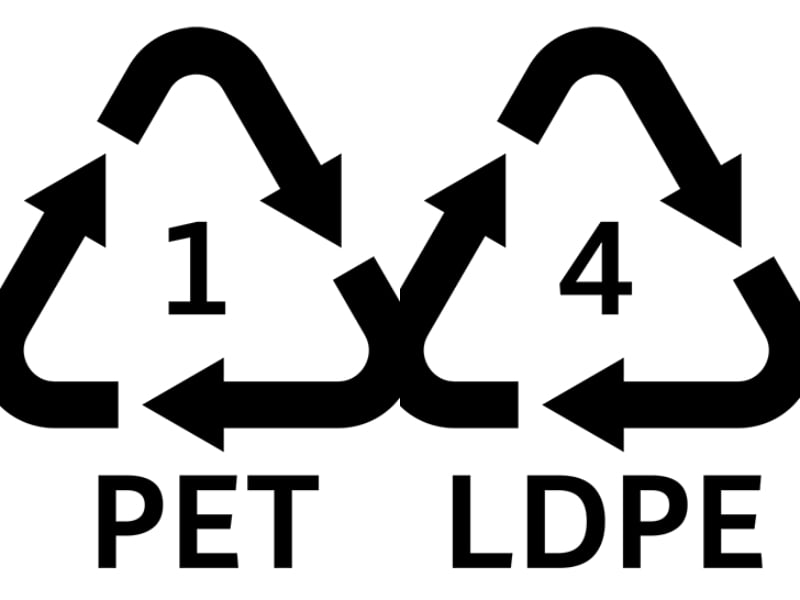

PET (RIC #1)

LDPE (RIC #4)

If your team asks, “Can these be recycled the same way?” the answer is: sometimes, but it depends on the recycler. Confirm before purchasing in volume.

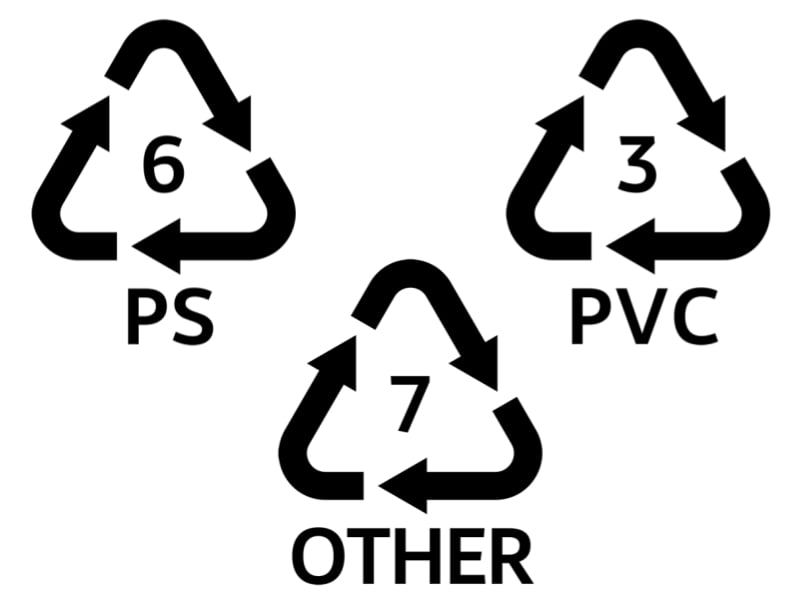

Plastics Often Not Accepted (Higher Rejection Risk)

Some plastics often face restrictions:

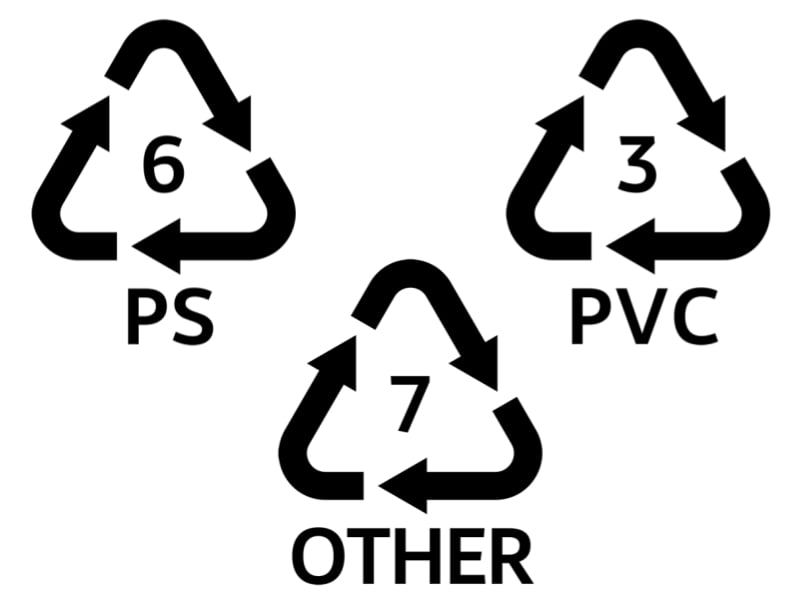

PVC (RIC #3)

PS (RIC #6)

RIC #7 “Other” (mixed or unknown plastics)

A frequent buyer question is: which plastics are commonly rejected? In many industrial streams, #3, #6, and #7 are the highest-risk types. They can contaminate other recycling lines or require special processing.

When “Recyclable” Material Becomes Hard to Recycle

Even HDPE or PP pallets can be rejected if the design creates extra processing work. This is usually caused by mixed or bonded parts.

Watch for these issues:

- •Rubber pads that cannot be removed

- •Heavy coatings or strong adhesives

- •Foam-filled structures

- •Composite additives (fiber or mineral-filled)

If recyclability matters, keep the design simple. Single-resin pallets with removable accessories are usually easier to handle.

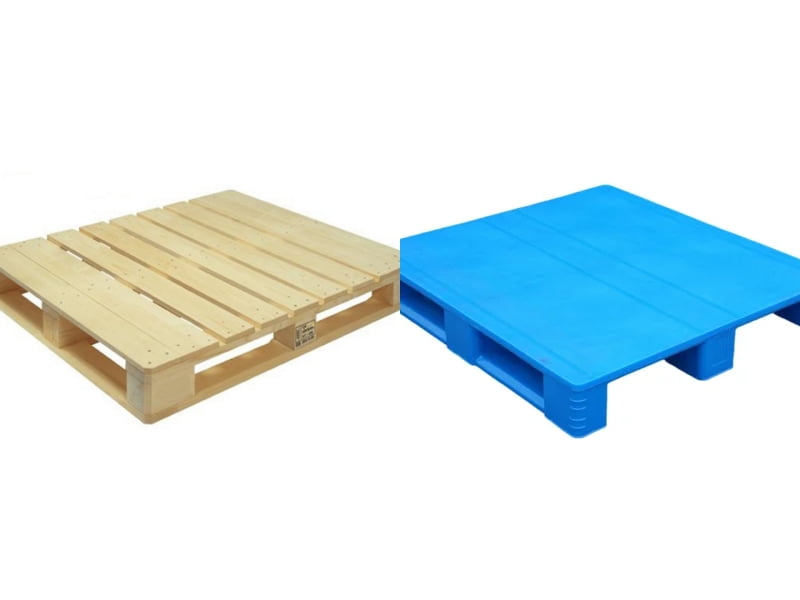

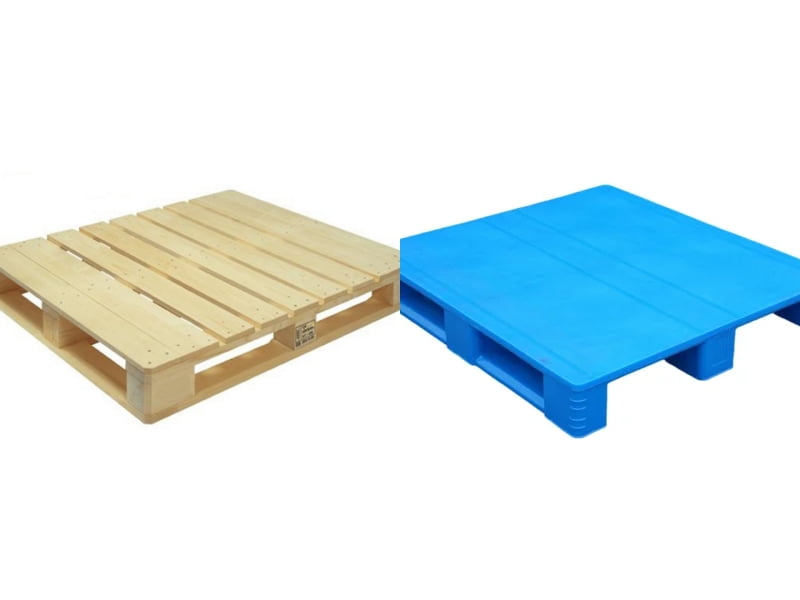

Plastic Pallets vs Wood—What Makes the Real Difference?

If your team is comparing plastic and wood pallets, the real question is not “which is cheaper today,” but which one stays reliable longer and creates less operational risk over time. Once you evaluate lifespan, hygiene, export compliance, and end-of-life control, plastic pallets usually deliver a clearer long-term advantage.

Lifespan and Replacement Rate

Wood pallets often fail sooner due to broken boards, loosened nails, and inconsistent repairs. That means more sorting, more downtime, and more repurchase cycles.

Plastic pallets are designed for repeat use and stable geometry, so they usually last longer and reduce replacement frequency—especially in high-turn logistics.

Damage Risk and Load Stability

Wood pallets can splinter, crack under uneven loads, and create sharp edges that damage cartons or bags. They also change condition faster when exposed to moisture.

Plastic pallets keep a consistent structure, which improves load stability and reduces product damage during handling, stacking, and transport.

Hygiene and Pest Control

Wood absorbs moisture and can hold odor, mold, or residue. It can also become a carrier for pests, which is a serious concern in food, pharma, and clean production.

Plastic pallets are non-absorbent and easier to wash. They do not splinter and do not create nesting conditions, making hygiene control more predictable in regulated environments.

Export Compliance and Border Readiness

Wood pallets often require ISPM 15 treatment and stamping for export. That adds time, documentation, and inspection risk.

Plastic pallets are generally ISPM 15-exempt, so export workflows become simpler, faster, and less likely to be delayed by compliance issues.

End-of-Life Control and Sustainability Outcome

Wood pallets are often repaired many times, but once they degrade, recovery options vary by region and condition. Many end up downcycled or disposed.

Plastic pallets offer stronger end-of-life control when HDPE or PP is used. With the right resin and clean design, they can enter industrial recycling streams and support landfill reduction targets with more consistency.

In short, wood pallets can work for basic one-way shipping, but plastic pallets are often the better choice when your operation needs repeatable performance, hygiene confidence, export readiness, and a more controllable sustainability path.

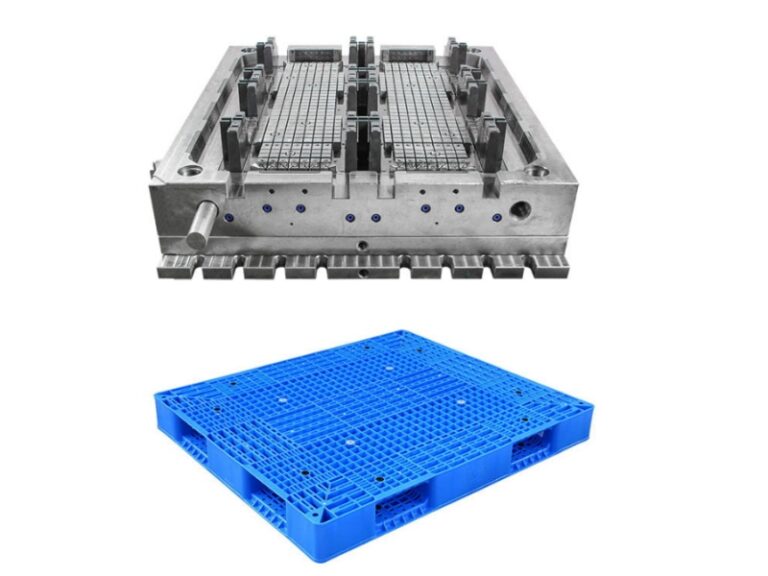

From a Plastic Pallet Manufacturer: Turn “Recyclable” Into a Supply Chain Advantage

Plastic pallets are recyclable, but the real value comes when recyclability is designed into your system—right resin, clean structure, and a confirmed recycling channel. Once those basics are clear, your team is no longer “hoping it works.” You’re making a decision you can measure, defend, and scale with confidence.

Work with Enlightening Pallet: Recyclable Plastic Pallets Built for Real Operations

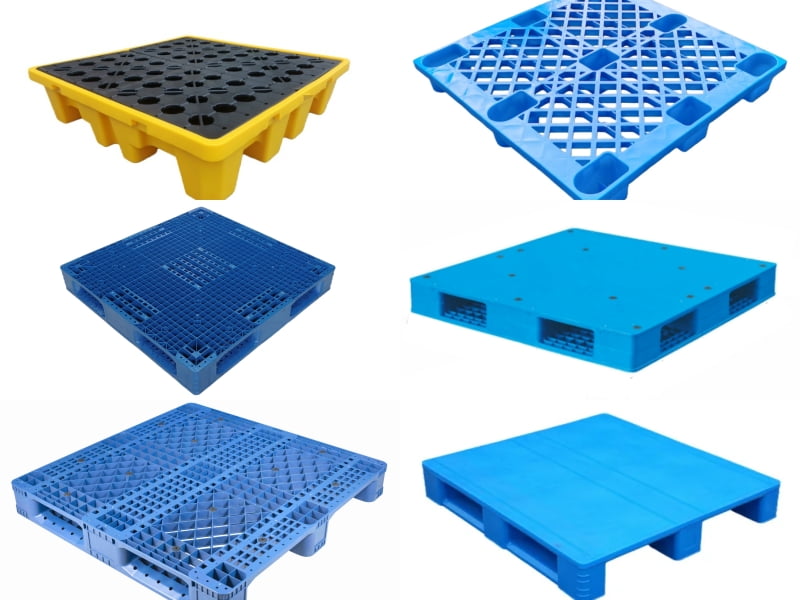

CN Plast is a professional plastic pallets manufacturer focused on one thing: helping your operation run with stable performance and lower long-term risk. Your site may need racking strength, hygiene compliance, export readiness, or consistent dimensions for automation. These are not “nice-to-have” features—they decide whether a pallet delivers value over hundreds of handling cycles.

When you share your working conditions, you don’t just get a product quote. You get a clear pallet specification built around your real use case, including:

-

•Material guidance: HDPE vs PP based on your environment and handling

-

•Structure selection for your load and storage method (floor stacking, racking, export shipping)

-

•Options to reduce failure and replacement frequency in daily operations

-

•Standardized designs that support easier sorting and recycling at end-of-life

Send your application details now—load type, racking setup, operating temperature, hygiene needs, and export routes.

Enlightening Pallet will respond with technical specs, bulk pricing, and the right pallet model recommendation so your next order is easier to approve, safer to run, and simpler to recycle.