Custom Plastic Pallet Solutions

From design confirmation to delivery supervision - we ensure every step of your custom pallet manufacturing meets your exact specifications with our proven 25+ year process.

How We Confirm Your Design Requirements

Initial Consultation & Requirements Gathering

We start with a comprehensive discussion about your specific needs - load capacity, dimensions, industry requirements, quantity, and timeline.

- Load capacity analysis

- Dimensional requirements

- Industry compliance needs

Technical Drawing & 3D Modeling

Our engineering team creates detailed technical drawings and 3D models based on your requirements. We provide multiple design iterations until the specifications perfectly match your needs.

- CAD technical drawings

- 3D visualization models

- Multiple design iterations

Material Selection

We recommend the optimal materials based on your application - whether it's HDPE for heavy-duty use, PP for chemical resistance, or specialized materials for food-grade applications. All materials are tested for compliance.

- Material recommendation

- Compliance testing

- Performance validation

Final Approval & Mold Development

Once you approve the final design and specifications, we begin mold development with precision tooling. Every detail is confirmed before production begins to ensure perfect results.

- Final design approval

- Precision mold creation

- Production readiness confirmation

What Customization Options Can You Choose

We offer injection molding, blow molding, or rotational molding

We adjust entry height, width, and direction to fit your forklifts

Any length × width × height you need

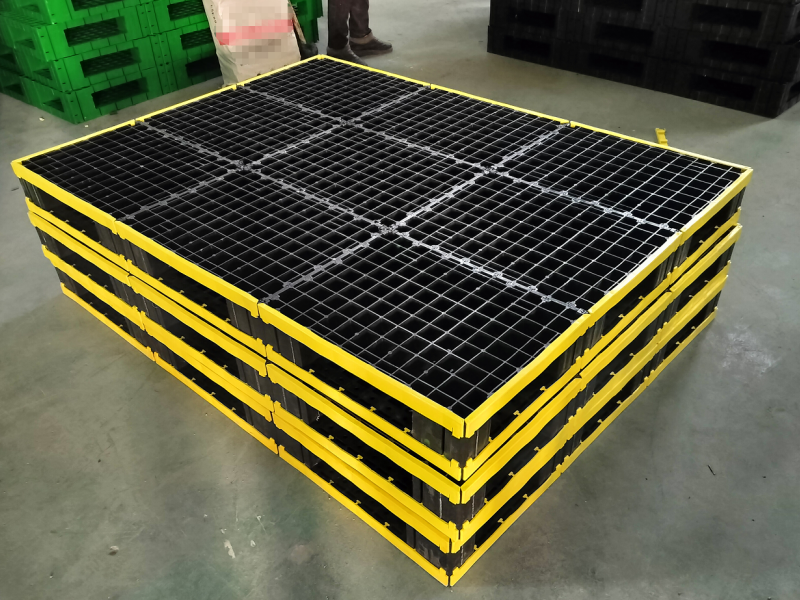

Choose solid or grid surface, double-faced or single-faced

Add anti-slip strips, steel reinforcements, or corner protection

Select 3-runner, 9-leg, cruciform, or perimeter base

Virgin HDPE/PP or recycled materials based on your needs

UV stabilizer, anti-freeze, anti-corrosion, or fire retardant options

Match any color in your branding

Apply your logo via screen printing, heat transfer, or in-mold labeling

Integrate barcodes, serial numbers, RFID, or QR codes

How You Can Supervise the Customization Process

Complete transparency and control throughout your custom pallet manufacturing journey

Real-Time Production Updates

Receive regular updates via email, WhatsApp, or phone calls about your production progress. We provide milestone notifications and address any concerns immediately.

Photo & Video Documentation

Visual proof of every production stage with detailed photos and videos. See your pallets being manufactured with our precision equipment and quality control processes.

Quality Control Reports

Detailed quality control reports at each inspection point. Our ISO 9001 certified process ensures every pallet meets your specifications before shipment.

Direct Communication Channel

Dedicated project manager available for direct communication. Ask questions, request changes, or get updates anytime during business hours.

Pre-shipment Inspection

Final inspection photos and approval process before shipment. You have the opportunity to review and approve the finished products before they leave our facility.

Complete Shipping Tracking

Full shipment tracking with documentation, customs clearance updates, and estimated delivery times. Stay informed until your pallets arrive safely.

Supervision Timeline

Design Approval

Day 1-3

Mold Creation

Day 4-15

Production

Day 16-25

Quality Check

Day 26-28

Shipment

Day 29-30

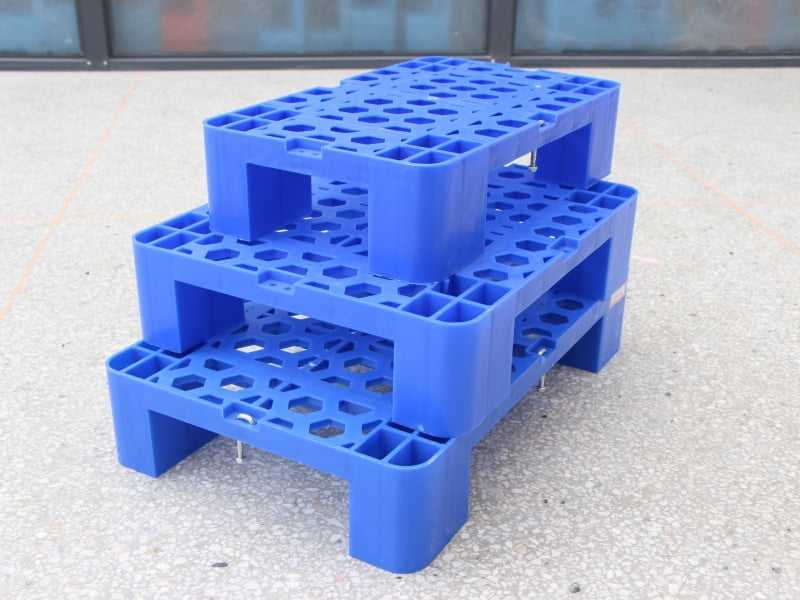

Our Custom Pallets Showcase

Transform your logistics with tailored plastic pallets. From colors to specifications, we customize every detail to match your unique business requirements and enhance your operational efficiency.

Color Customization

Match your brand identity with unlimited color options. From vibrant hues to subtle tones, we bring your vision to life.

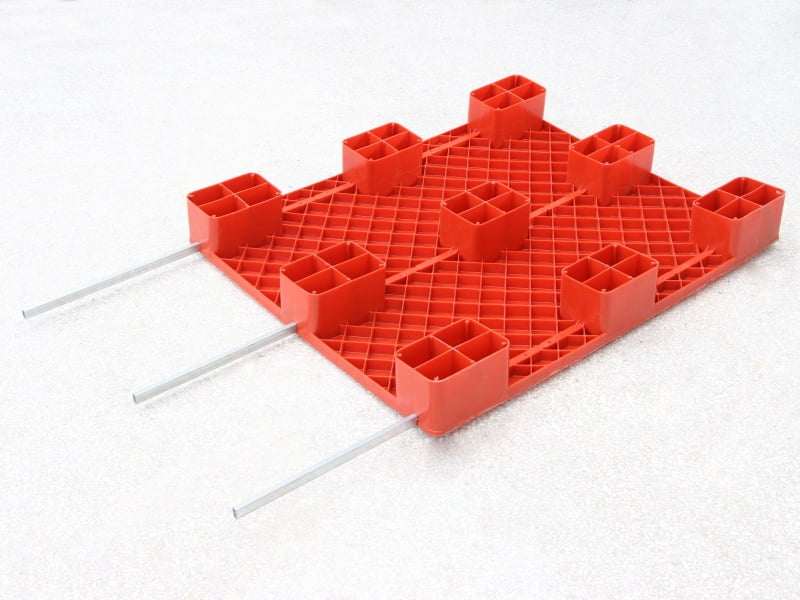

Steel Tube Integration

Enhance durability with integrated steel reinforcement tubes for heavy-duty applications and extended lifespan.

Size Specifications

Tailor dimensions to fit your exact storage and transportation needs. Custom sizes for optimal space utilization.

Slide Pallet Design

Smooth-sliding mechanisms for effortless handling and improved workflow efficiency in automated systems.

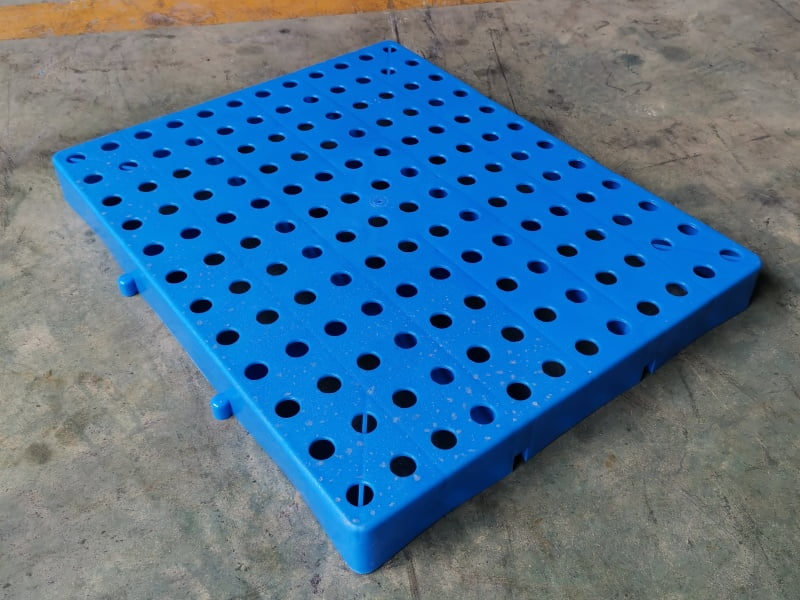

Waterproof Breathable Pallets

Advanced moisture-resistant technology to protect sensitive goods in humid environments and outdoor storage.

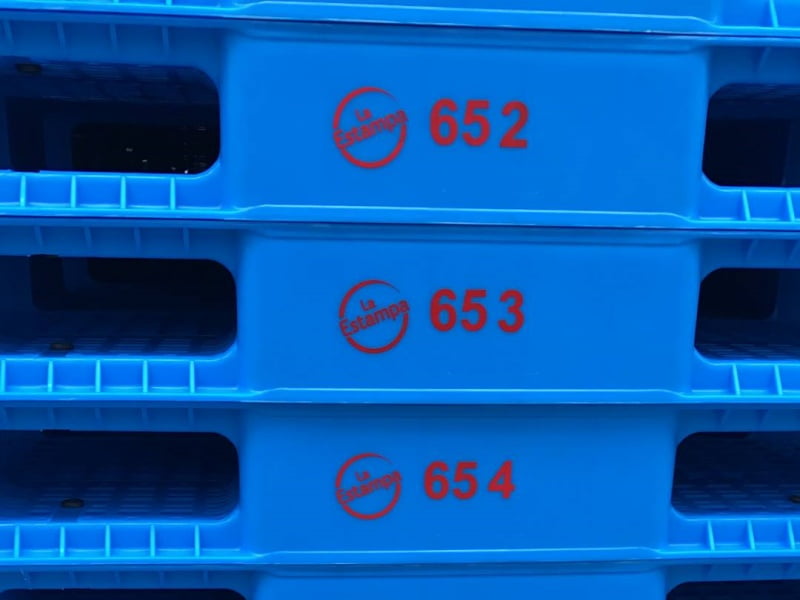

Logo Customization

Professional logo printing and embossing services to enhance brand visibility and corporate identity.

Modular Pallets

Modular interlocking design for flexible configurations and space-efficient storage solutions.

Moisture Proof Backing

Specialized cushioning boards for delicate items protection and shock absorption during transport.

Die-Casting Process

Advanced die-casting techniques for superior structural integrity and precision manufacturing quality.

Start Your Custom Project Today

Get a personalized quote for your custom plastic pallet requirements. Our experts will respond within 24 hours.