When it comes to food storage and transport, ensuring safety and durability is crucial. High-Density Polyethylene (HDPE) is a widely used plastic known for its strength, chemical resistance, and moisture barrier properties. But with so many materials available, you might wonder: Is HDPE really safe for food contact? The answer is yes.

This article explores why HDPE is a top choice for food packaging, focusing on its FDA compliance, non-leaching properties, and recyclability. We’ll break down the science behind its safety standards, how it compares to other plastics, and why it’s trusted by industries handling everything from dairy products to pharmaceuticals. By the end, you’ll have a comprehensive understanding of HDPE’s role in safe food storage and transport, helping you make an informed decision for your business or everyday use.

What is HDPE Plastic?

HDPE, or High-Density Polyethylene, is a thermoplastic polymer derived from ethylene. It’s known for its high strength and durability, which makes it a preferred material in many industries, including food packaging.

HDPE’s structure is tightly packed with minimal branching, giving it excellent chemical resistance and moisture barrier properties. These qualities make it an ideal choice for storing various food items. It’s also recyclable, marked with the recycling code #2, and can be molded into many different shapes, such as containers and bottles.

Is HDPE Plastic Food Safe?

Yes, HDPE is food-safe when it’s used appropriately. This means the plastic does not leach harmful chemicals into food, making it a reliable choice for food-contact materials. Both virgin HDPE and properly processed recycled HDPE meet the necessary safety standards for food packaging.

The material is biologically inert, which means it doesn’t react with food, preserving both its safety and quality. HDPE is also FDA-compliant under the guidelines of 21 CFR 177.1520, making it a safe option for storing food and beverages.

FDA and EU Regulations for Food-Grade HDPE

The U.S. Food and Drug Administration (FDA) plays a crucial role in ensuring that materials used in food packaging are safe. Virgin HDPE is FDA-approved for direct food contact, which means it meets the necessary purity and safety standards. For recycled HDPE, the FDA reviews the material case by case to confirm that it doesn’t contain harmful contaminants.

In the EU, Regulation (EU) No 10/2011 governs the use of plastic materials in food packaging, ensuring that HDPE food-contact materials meet strict migration limits to prevent harmful substances from transferring to food.

How to Identify Food-Grade HDPE

Food-grade HDPE is often marked with the recycling code “2”, usually shown inside the triangular chasing arrows symbol. This code confirms the material is high-density polyethylene, which is commonly used for food-contact packaging such as milk jugs, juice bottles, and food storage containers. When you are selecting containers for food storage, checking for the HDPE #2 symbol is one of the fastest ways to avoid using unsuitable plastic types.

However, the recycling code alone does not automatically guarantee that the product is truly food grade in every case. For higher-risk applications, it is smarter to look for additional proof such as FDA compliance statements, EU food contact compliance, or supplier documentation that confirms the resin and additives meet regulated standards. If you are buying in bulk for production or distribution, request supporting documents such as a Declaration of Conformity (DoC) or material certification, especially when recycled content is involved. This extra verification helps you reduce compliance risk and ensures the packaging is safe for real-world food contact use.

Key Benefits of HDPE

HDPE is one of the most trusted materials in food packaging because it combines safety, durability, and stable performance. If you’re selecting containers or packaging systems for food storage, here are the key advantages that make food-grade HDPE a reliable choice:

Strong and impact-resistant

HDPE handles drops, stacking pressure, and daily handling better than many plastics. This reduces cracking risk during storage and distribution.

Excellent chemical resistance

HDPE performs well with salt, sugar, oils, and most food ingredients, so the container keeps its structure and does not react with the product.

Low migration risk (non-leaching behavior)

When made with virgin, compliant resin, HDPE is chemically inert and does not easily release substances into food under normal use conditions.

Non-porous and hygienic surface

HDPE does not absorb moisture like porous materials. This helps prevent odor retention and reduces the risk of residue buildup after cleaning.

Reliable moisture barrier

It blocks moisture transmission well, helping food maintain freshness, texture, and shelf stability, especially for dry goods and ingredients.

Wide temperature adaptability for storage and logistics

HDPE stays stable in common cold-chain conditions and typical warehouse environments. (Avoid high-heat use unless the product is rated for it.)

Lightweight but structurally stable

Compared with heavier alternatives, HDPE improves handling efficiency and reduces shipping weight—useful for both internal transport and export operations.

Cost-effective for large-scale packaging

HDPE offers strong performance at a competitive cost, which is why it’s widely used in mass food packaging and repeated-use applications.

Recyclable and widely accepted

HDPE is marked with the recycling code #2, making it one of the most commonly recycled plastics in global recycling systems.

Conditions for Safe Use of HDPE in Food Packaging

HDPE is safe for storing food under normal conditions, but it’s important to note that exposure to extreme heat or fatty foods can affect its integrity. Unless specifically labeled as microwave-safe, HDPE should not be used in microwaves or subjected to high-temperature cooking. Always ensure that containers are clean before reusing them to prevent contamination.

HDPE vs Other Plastics: What’s Best for Food Packaging?

-

HDPE vs PET: While PET is known for its clarity and gas barrier properties, HDPE is more durable and resistant to chemicals, making it better suited for food storage that requires strength and protection.

-

HDPE vs PP: Polypropylene (PP) offers better heat resistance, which makes it ideal for microwaveable containers. However, HDPE excels in chemical resistance and impact resistance, making it suitable for heavier-duty food packaging.

-

HDPE vs LDPE: While LDPE is more flexible and used for squeeze bottles and films, HDPE provides better moisture resistance and is more rigid, making it suitable for food storage containers.

Let’s take a look at the recycling code for HDPE

One of the major benefits of HDPE is its recyclability. With a #2 recycling code, it’s easy to recycle and repurpose into other products like plastic lumber and garden furniture, reducing its environmental footprint. Moreover, its lightweight nature helps to reduce transportation costs and carbon emissions throughout the supply chain.

Recycling HDPE also supports the circular economy, where materials are reused to create new products. By choosing sustainable HDPE packaging, businesses can minimize waste and make a positive environmental impact.

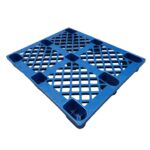

Practical Applications of HDPE Pallets in Food and Pharmaceutical Industry

HDPE is widely used in the food and pharmaceutical industries for transporting and storing products. HDPE pallets are often used to safely move perishable foods, such as dairy products and frozen goods, as well as pharmaceuticals that require temperature-sensitive storage.

HDPE pallets are durable, resistant to moisture, and protect the products from external contamination. Given its ability to withstand the rigors of transportation and handling, HDPE is an excellent choice for logistics and bulk storage of food and medications.

The material’s non-leaching properties make it safe for FDA-compliant food and drug packaging, ensuring that the products remain safe from harmful chemical exposure during transportation and storage.

Conclusion: Trust HDPE for Safe and Sustainable Food Packaging

At CNplast, we provide high-quality HDPE plastic pallets that ensure food safety, compliance, and sustainability. Our FDA-approved and recyclable HDPE pallets are designed to meet the demanding needs of the food and pharmaceutical industries, offering superior chemical resistance, durability, and moisture protection.

By choosing food-grade HDPE pallets from CNplast, you ensure compliance with global standards and support sustainable practices in your supply chain. With our expertise in plastic pallets, we provide robust, eco-friendly solutions designed to protect your products during transport and storage.

Investing in HDPE solutions from CNplast means partnering with a trusted plastic pallet manufacturer committed to safety, sustainability, and quality. Let us help you provide the best in food safety while driving your business forward.