How to Clean Plastic Pallets: A Complete Guide for Businesses

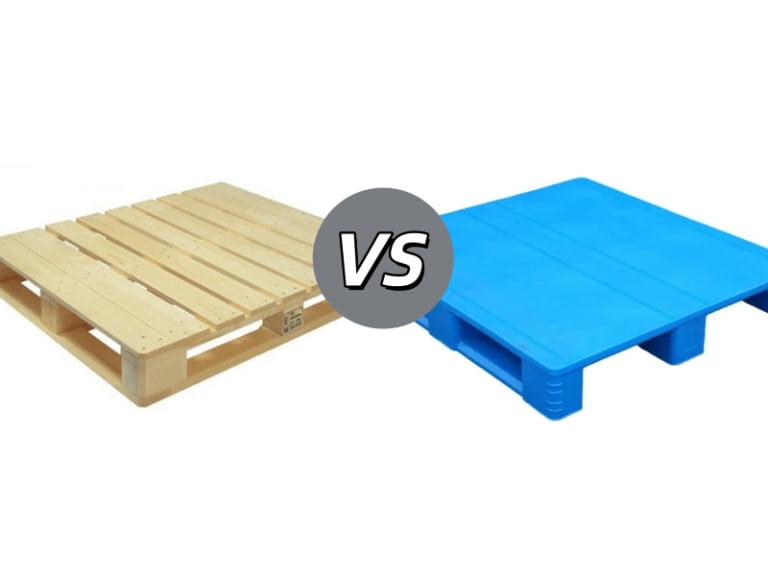

When it comes to maintaining your logistics and operations, the cleanliness of your plastic pallets plays a pivotal role. Whether you’re handling food, pharmaceuticals, or industrial products, the condition of your pallets directly impacts efficiency, safety, and compliance with regulations. Yet, despite their durability, plastic pallets can accumulate dirt, debris, and even chemical residues, which, if left unchecked, can lead to contamination, damaged goods, and increased operational costs.

In this guide, we’ll walk you through the best cleaning practices for plastic pallets—whether you’re dealing with small volumes or high hygiene requirements. From manual cleaning techniques to industrial washing systems, we’ll cover everything you need to ensure your pallets are safe, hygienic, and ready for the next cycle of use. Let’s dive in and discover how simple cleaning steps can extend the life of your pallets and elevate your business operations.

What to Do Before Cleaning Plastic Pallets? (Pre-Cleaning Prep)

Before jumping into cleaning, there are a few crucial steps to take. Proper preparation will ensure your plastic pallets are cleaned effectively and ready for use.

Inspect Pallets for Damage First

Start by checking your plastic pallets for cracks, chips, or warping. These issues can compromise the structural integrity of the pallets and should be addressed before cleaning. If you spot any damage, set those pallets aside for repair or replacement. Additionally, look for stubborn stains or chemical residues from previous shipments. Identifying these will help you focus on those areas during the cleaning process.

Gather the Right Cleaning Supplies

To clean plastic pallets efficiently, you need to have the right tools on hand. Use a mild, plastic-safe detergent, especially if your pallets are FDA-approved or food-grade. You’ll need a hose with a jet nozzle, a soft-bristled brush for scrubbing, and a pressure washer if you’re cleaning a large number of pallets. Don’t forget personal protective equipment (PPE) like gloves, goggles, and non-slip boots to ensure safety. Make sure you also have drying tools—towels or an industrial drying rack—to speed up the drying process.

Clear Loose Debris Quickly

Before cleaning, use anair compressor or hose to remove dust, dirt, leaves, or other loose debris. For pallet boxes or nestable pallets, ensure to empty out any contents. If your pallets have a closed-deck design, flip them over to clean hidden debris from the underside.

What Are the 3 Best Ways to Clean Plastic Pallets? (Core Cleaning Methods)

When it comes to cleaning, there are three effective methods to choose from. The right choice depends on your volume, budget, and the level of cleanliness required.

Manual Cleaning (Best for Small Volumes & Low-Budget Teams)

Manual cleaning is straightforward and economical, especially if you’re dealing with a few pallets. Here’s how it works:

- Pre-rinse the pallets with water to loosen grime.

- Apply plastic-safe detergent and scrub the surface with a brush, paying extra attention to grooves and stains.

- Rinse thoroughly to remove all soap residue.

- Dry using towels or air-dry completely.

While it’s low-cost, manual cleaning is time-intensive and may not deliver consistent results, especially for larger operations.

Pressure Washing (Best for Medium Volumes & Heavy Soiling)

For a faster and more effective cleaning process, pressure washing is a great option. Follow these steps:

- Pre-rinse the pallets with low-pressure water to remove loose dirt.

- Apply detergent (warm water + food-safe or industrial cleaner).

- Use a pressure washer with 1000-2500 PSI to clean thoroughly, adjusting the pressure based on pallet material.

- Finish with a final rinse and optional drying with hot air.

Pressure washing is quicker and more effective than manual cleaning, but it requires space for the setup and an initial equipment investment.

Industrial Automated Washing (Best for High-Volume & High-Hygiene Industries)

For businesses with high pallet turnover or those in regulated industries, industrial automated washing is the best solution. The process includes:

- Pre-wash to remove loose dirt.

- Main wash with hot water and detergent.

- Rinse to remove any soap residue.

- Drying with hot air.

These machines offer consistent, high-efficiency cleaning, saving time and labor. However, they require significant capital investment and space.

How to Dry & Store Cleaned Plastic Pallets to Extend Life? (Post-Cleaning Care)

After cleaning your plastic pallets, proper drying and storage are essential to ensure they last as long as possible.

Dry Pallets Thoroughly (No Moisture = No Mold/Bacteria)

Once you’ve cleaned your pallets, make sure they’re completely dry before using or storing them. Air-dry pallets in a clean, ventilated area, but avoid direct sunlight, which can cause UV damage. For quicker drying, consider using industrial dryers—particularly if your pallets are food-grade or used in pharma industries. Wipe off any remaining water spots using microfiber towels for a spotless finish.

Store Clean Pallets Properly

Proper storage plays a significant role in extending the lifespan of your plastic pallets. Store them in dry, shaded spaces to avoid exposure to chemicals or extreme temperatures. Stack pallets evenly, ensuring they’re not overloaded to prevent warping. For pallet boxes or nestable pallets, stack them empty and closed to keep the interiors clean. Always separate clean pallets from dirty ones to prevent cross-contamination.

What Are the Hygiene Rules for Cleaning Plastic Pallets in Food/Pharma? (Industry-Specific Compliance)

In certain industries, like food and pharmaceuticals, cleaning plastic pallets goes beyond general hygiene. It’s crucial to adhere to specific rules to ensure safety and compliance.

FDA/ Food Industry Cleaning Requirements

For food-grade pallets, always use non-toxic, food-safe detergents and avoid harsh chemicals like bleach. Pallets should be sanitized at temperatures of 165°F or higher to kill harmful bacteria. After cleaning, ensure no soap or chemicals are left on the surface, especially if the pallet is used for raw meat, dairy, or ready-to-eat food.

GMP/ Pharma Industry Cleaning Standards

In the pharmaceutical industry, cleanliness is crucial to prevent cross-contamination. Sterilize pallets to eliminate any pathogens that could contaminate drugs. Keep a detailed cleaning log for audits, including the date, time, method, and operator involved. Avoid reusing pallets for different drug categories without complete sanitation.

Chemical Industry Cleaning Rules

For industrial pallets used in chemicals, it’s important to neutralize any corrosive residues before cleaning. Use chemical-resistant detergents for stubborn stains like oils and solvents, and dispose of wastewater according to local environmental guidelines.

Which Cleaning Method Saves the Most Cost for Your Business? (Cost & ROI Analysis)

Choosing the right cleaning method for your business involves considering both the upfront costs and long-term savings. Here’s a cost breakdown:

Cost Breakdown of Each Cleaning Method

Manual Cleaning: Low labor cost + detergent cost (no equipment investment needed).

Pressure Washing: Equipment cost + water, electricity, detergent, and labor.

Industrial Automated Washing: High capital investment + ongoing maintenance + minimal labor.

How to Calculate ROI for Industrial Washers

When evaluating industrial washing systems, consider the labor savings compared to manual or pressure washing. Automated systems also use 30-50% less water and chemicals, helping reduce operational costs. Additionally, proper cleaning can extend the lifespan of your pallets, reducing the need for replacements.

Budget-Friendly Tips for Small Businesses

If you’re working with a small budget, consider renting a pressure washer instead of buying one. For light stains, homemade cleaners like a vinegar-water mix can work wonders. Schedule group cleaning sessions to reduce labor time and improve efficiency.

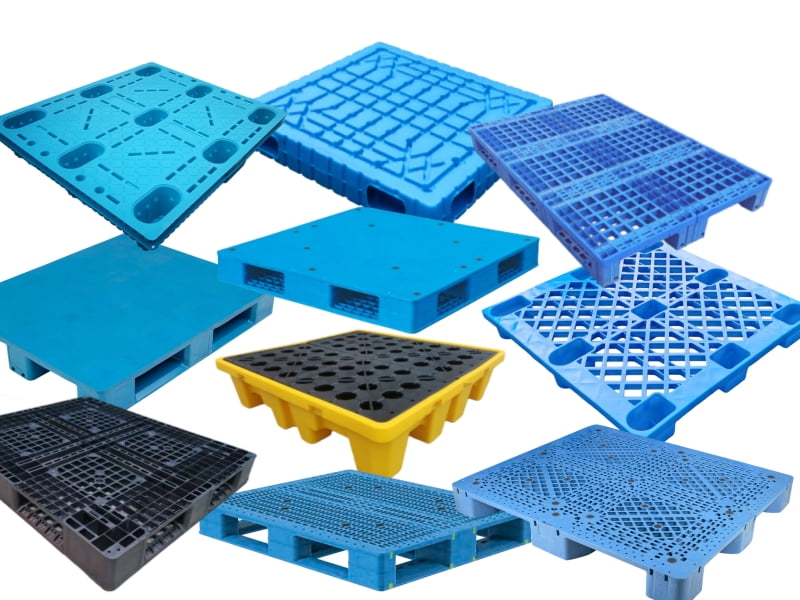

How to Clean Different Types of Plastic Pallets? (Material & Design Adaptation)

Different types of plastic pallets require specific cleaning methods based on their material and design. Here’s how to adapt your cleaning routine:

Clean by Plastic Material

HDPE Pallets: These are durable and can withstand high pressure (1500–2500 PSI) and hot water (up to 180°F).

PP Pallets: Use low-to-medium pressure and avoid high-alkaline detergents.

Food-Grade Plastic Pallets: Only use NSF-certified cleaners and avoid abrasive cleaning tools to preserve the integrity of the material.

Clean by Pallet Design

Open-Deck Pallets: Simply rinse through the gaps to remove hidden dirt—no need to flip the pallet.

Closed-Deck Pallets: Flip the pallet to clean the underside and use brushes for the flat surfaces.

Plastic Pallet Boxes: Empty the contents, disassemble if foldable, clean both the interior and exterior, and ensure thorough drying.

Nestable/Stackable Pallets: Separate nested units before cleaning to prevent trapped dirt and debris.

How to Clean Plastic Pallets Safely & Eco-Friendly? (Safety & Sustainability)

Cleaning plastic pallets doesn’t have to come at the expense of safety or the environment. Follow these tips to clean responsibly.

Worker Safety Best Practices

Always use non-slip mats in cleaning areas to prevent accidents. Never direct a pressure washer at people to avoid injuries. Ensure workers wear proper PPE, including gloves, goggles, and boots, especially when handling chemicals or heavy pallets.

Eco-Friendly Cleaning Tips

Use biodegradable, phosphate-free detergents to minimize your environmental impact. Install water recycling systems in your industrial washers to reduce water waste, and opt for hot water or steam cleaning to minimize chemical use.

Reduce Environmental Impact of Pallet Care

Instead of replacing damaged pallets, consider repairing them to extend their lifecycle. Choose recyclable plastic pallets and opt for solar-powered dryers in industrial cleaning systems to further reduce energy consumption.

How to Fix Sticky Residue & Tough Stains on Plastic Pallets? (Troubleshooting Common Issues)

If your pallets have sticky residues or tough stains, these tips will help you solve the problem efficiently.

Remove Sticky/ Greasy Residue

Use degreasers, especially for food pallets, and pair them with hot water pressure washing. For an eco-friendly solution, scrub with a baking soda and water paste.

Eliminate Mold & Mildew

Sanitize pallets with steam or hot water at temperatures above 165°F. Dry pallets immediately to prevent mold regrowth.

Clean Chemical/ Oil Stains (Industrial Pallets)

Use solvent-based cleaners for tough industrial stains, and always neutralize acidic or alkaline residues before rinsing.

Fix Discoloration (UV/ Stain Damage)

Use plastic-safe brighteners (avoid harsh bleaches) and store pallets out of direct sunlight to prevent further discoloration.

FAQs: Everything You Need to Know About Cleaning Plastic Pallets (Quick Answers)

For quick solutions to common questions, here’s everything you need to know.

How Often Should I Clean Plastic Pallets?

Food/Pharma: After every use

Industrial/Logistics: Monthly (or after heavy soiling)

Chemical: After each chemical shipment

Can I Use Bleach to Clean Plastic Pallets?

No, bleach degrades plastic and leaves toxic residue. Use food-safe sanitizers or hot water/steam instead.

How Do I Know If My Pallet Is Clean Enough?

Visual check: No stains, residue, or debris

Hygiene check: ATP testing (for food/pharma)

Smell check: No odors (sign of bacteria/mold)

Can I Clean Water Bottle Racks & Pallet Boxes the Same Way?

Yes, follow the same methods but adjust for the design. Disassemble racks or boxes and clean small crevices with brushes.

How Long Does a Cleaned Plastic Pallet Last?

With regular cleaning and proper storage, plastic pallets can last 10+ years—much longer than neglected pallets (3-5 years).

Why Proper Plastic Pallet Cleaning Matters for Your Business?

At CNplast, we understand that for businesses relying on plastic pallets—especially in industries like food, pharmaceuticals, or chemicals—cleaning is not just a matter of hygiene, but a critical factor in ensuring operational efficiency, compliance, and longevity. Clean, reliable pallets help improve your workflows, maintain safety standards, and reduce costs over time. As leading plastic pallet manufacturers, we provide tailored solutions that meet the highest standards of durability and cleanliness.

Don’t let pallet issues hold your business back. Contact us now to explore our range of high-quality, cost-effective plastic pallet solutions, customized for your needs, and let us help you optimize your operations and save on long-term costs.