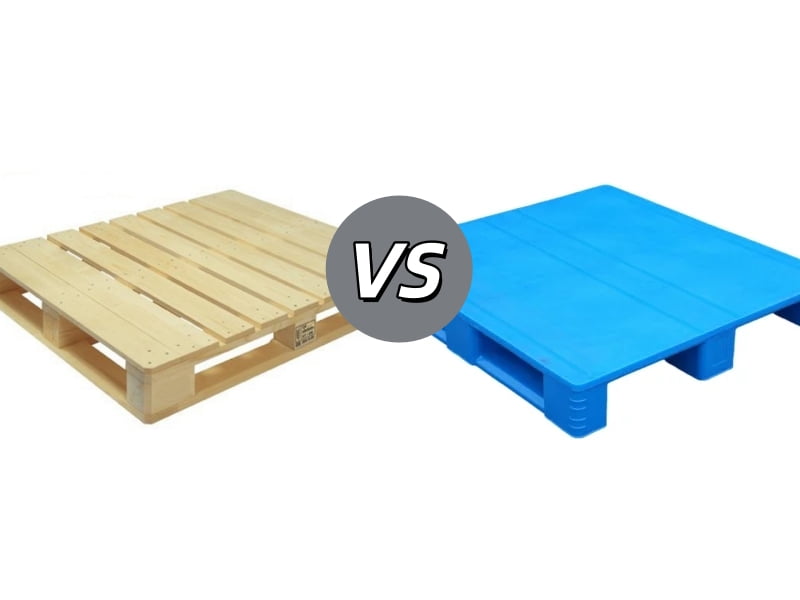

The short answer is yes, but the real decision comes down to choosing the material that best suits your specific needs. If you are dealing with frequent pallet damage, heavy loads, or stringent hygiene standards, plastic pallets might be the better option. In this article, we’ll walk you through how wood and plastic pallets compare in terms of load capacity, durability, cost, and more. Let’s dive into how each material performs in real-world conditions, helping you make the most informed decision for your business.

What Are the Material Differences Between Wood and Plastic Pallets?

When you’re looking at wood pallets in your warehouse, you’re typically seeing softwoods like pine, spruce, and fir, or hardwoods such as oak and maple. These materials give you solid initial strength, but here’s what you’ll notice over time—they’re much more vulnerable to the wear and environmental factors your operation throws at them. Your plastic pallets, on the other hand, are primarily constructed from HDPE (high-density polyethylene) or PP (polypropylene). What makes these materials valuable for your facility is their high strength and durability, especially when your pallets face harsh environments that would damage wood.

What Do Static and Dynamic Load Really Mean for Your Pallets?

Understanding the weight your pallets can bear when stationary and in motion is crucial for achieving efficient operations in your warehouse. Here’s what you need to consider — static and dynamic load-bearing capabilities are key factors that vary significantly between the plastic pallets and wooden pallets you’re evaluating. This is where your material choice truly matters, directly impacting both your warehouse efficiency and how long your pallets will last under your specific operating conditions.

Plastic Pallets

- Static Load Capacity: 4,000–6,000 kg

- Dynamic Load Capacity: 1,000–2,000 kg

Plastic pallets are known for their high load-bearing capacity, especially in demanding environments. These pallets can also be reinforced with steel rods to further enhance their strength.

Wood Pallets

- Static Load Capacity: 3,500–4,500+ lbs (1,590–2,040 kg)

- Dynamic Load Capacity: 2,000–2,800+ lbs (900–1,270 kg)

Wood pallets are typically less durable than plastic in terms of load-bearing capacity. They are also prone to wear over time, reducing their effectiveness.

How Do Wood and Plastic Pallets Perform in Extreme Temperature Conditions?

Temperature extremes can significantly impact pallet performance. Let’s compare how wood pallets and plastic pallets (made from HDPE and PP) perform in both cold and hot environments.

Cold Temperature Performance

- Wood Pallets: Wood fibers expand and contract with temperature swings, making them brittle and prone to cracking under load in freezing conditions.

- HDPE and PP Plastic Pallets: These materials remain stable and resistant to impact at temperatures below zero degrees Celsius, capable of withstanding extreme low temperatures of -40℃. Therefore, they are highly suitable for the refrigeration and cold chain logistics sectors, as wooden pallets may fail due to water absorption and cracking in these areas.

High Temperature Performance

- Wood Pallets: Heat causes the wood fibers in your pallets to dry out and warp, weakening your pallet structure and increasing the risk of splintering that can damage your products. If you’re operating in heated warehouses or shipping through hot climates, your wood pallets typically withstand temperatures up to 50–60°C before they begin to degrade and compromise your load stability.

- HDPE and PP Plastic Pallets: Both materials are highly resistant to heat, with HDPE’s melting point at 120–130°C and PP at an even higher temperature. Plastic pallets can withstand temperatures up to 60–80°C, making them suitable for most warehouse heat scenarios

What’s the Real Cost of Wood vs. Plastic Pallets Over Time?

While it’s easy to compare upfront prices, the true cost of a pallet extends far beyond the initial purchase. Let’s break down the total cost of ownership (TCO) for wood and plastic pallets, including hidden costs and long-term benefits.

Wood Pallets

- Upfront Cost: Lower initial cost compared to plastic.

- Maintenance Costs: Wood pallets often require more frequent repairs and replacements due to damage from moisture, pests, and wear.

- Shorter Lifespan: Typically last 2–5 years, increasing operational costs as they degrade over time.

- Disposal Costs: At the end of their life cycle, wood pallets often end up in landfills, which adds to disposal fees and environmental impact.

Plastic Pallets

- Upfront Cost: Higher initial purchase price.

- Lifespan and Durability: Plastic pallets last 8–15 years, significantly reducing replacement costs over time.

- Maintenance and Cleaning: They require less maintenance, and their resistance to moisture and pests further lowers operational costs.

- Recyclability: At the end of their life cycle, plastic pallets can be fully recycled into new pallets or other plastic products, reducing disposal costs and contributing to a circular economy.

Which Industries Should Switch to Plastic Pallets?

Certain industries benefit more from plastic pallets than others. Let’s take a look at where they shine:

- Food & Beverage: Hygiene and wash-down requirements make plastic pallets ideal for this industry. They are easier to sanitize and comply with food safety standards.

- Pharmaceutical: Strict FDA compliance and sterilization needs make plastic pallets the preferred choice in pharma logistics.

- Warehousing & Logistics: Plastic pallets are perfect for high-bay racking and long-term use due to their durability and rack compatibility.

How Does Design Affect Strength?

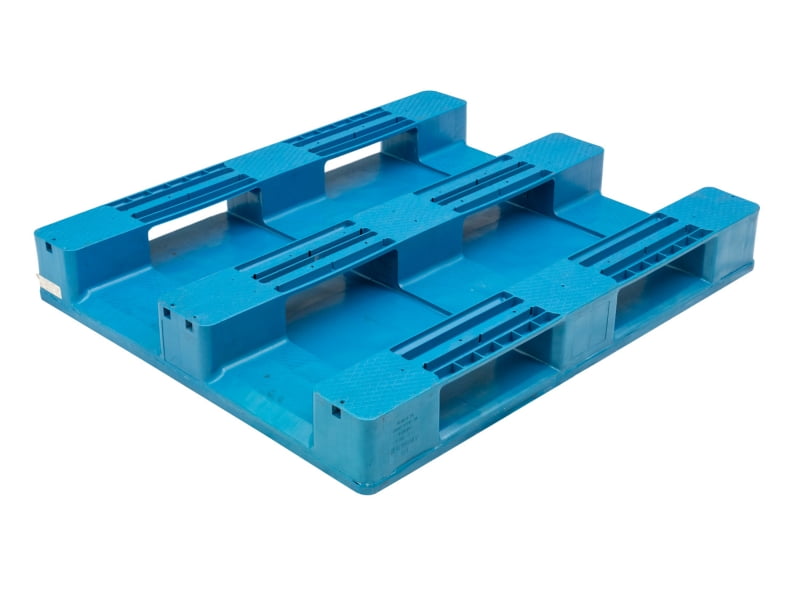

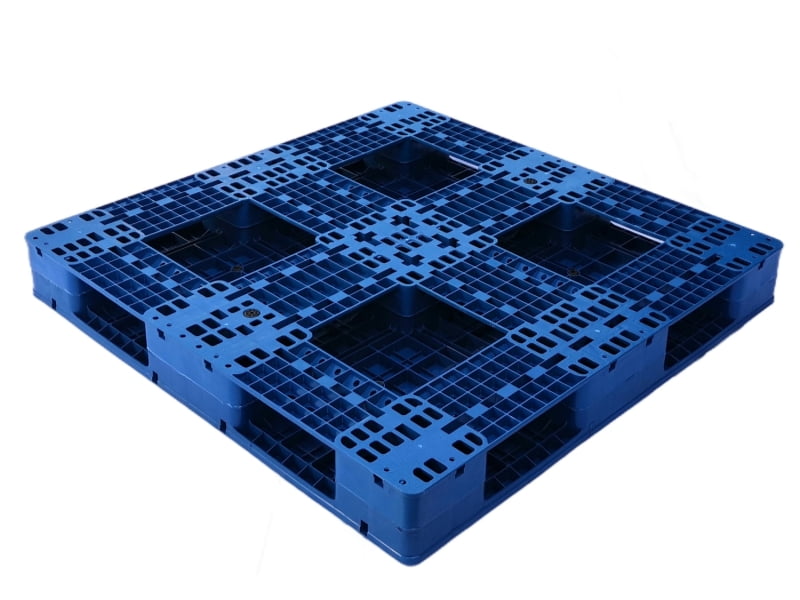

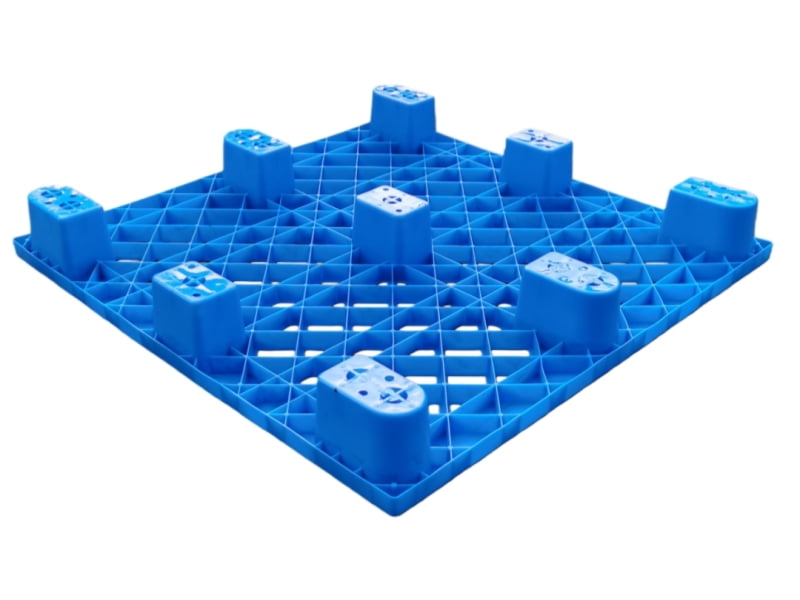

Your pallet’s load rating isn’t “just a number”—it reflects the structure supporting your operations. Consider your usage: floor storage, forklift handling, and racking stress different base areas. That’s why runner-style and reversible designs handle heavier loads than leg-style designs, and why steel reinforcement works with some bases but not others. Choosing the right plastic pallet is of vital importance:

How to Actually Choose a Plastic Pallet — Material, Design & Quality Checklist

Not all plastic pallets are created equal. Here’s a checklist to ensure you choose the right one for your needs:

- Material: Choose between HDPE and PP based on your strength and environmental requirements.

- Design: Consider whether you need a solid deck for hygiene, a reinforced design for heavy-duty use, or a nestable pallet for space-saving.

- Certifications: Look for ISO 9001, FDA approval, and other necessary certifications to guarantee quality and compliance.

Make the Right Choice for Your Business — Switch to Plastic Pallets

After reviewing the key differences between wood and plastic pallets, it’s clear that plastic pallets offer superior durability, load capacity, and cost-effectiveness over time. Think about it — whether you’re in warehousing, logistics, or food processing, the long-term savings from plastic pallets are undeniable. They provide better performance, fewer repairs, and a cleaner, more reliable solution for your operations.

As a trusted plastic pallet manufacturer, CN Plast offers customized solutions tailored to your specific needs. Don’t let outdated pallets hold back your efficiency — contact us today to get the most reliable, durable, and cost-effective pallets for your business. Start enjoying the benefits of smarter logistics and improved productivity. Let us help you make the right choice for your business’s future.