If you are comparing options, the goal is not to memorize every material. It is to understand what each one is best at—and why modern operations often move toward plastic for consistent performance and easier control. This guide breaks down the materials in plain language, so you can quickly recognize what fits your environment and what to avoid wasting time on.

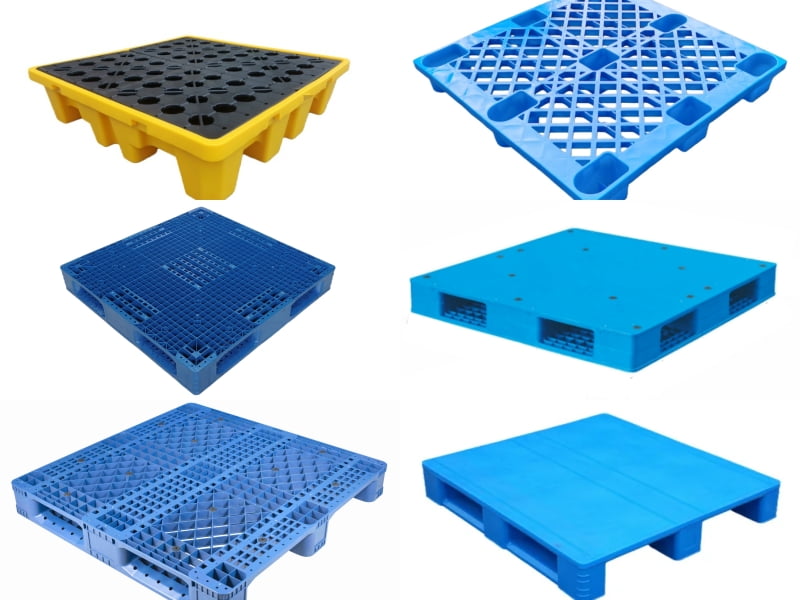

HDPE Pallets Explained ——The Most Common Plastic Pallet Material

HDPE pallets are widely used because they balance strength, toughness, and cost. If you need a dependable “all-around” material, HDPE is often the first place to look. In many sectors, HDPE pallets are the default spec for reusable plastic pallets.

What HDPE is known for in pallet applications

HDPE (high-density polyethylene) is known for durability, corrosion resistance, and good impact resistance. It is also lightweight compared with many alternatives, which helps with handling and freight.

If you want one plastic resin that covers most normal logistics conditions, HDPE is usually the safe baseline.

PP Pallets Explained ——When Extra Rigidity and Chemical Resistance Matter

PP plastic is often chosen when you need higher rigidity and stronger chemical resistance. If your environment is harsher, PP may feel more “stable” under load.

This is why some industrial users specify PP plastic pallets for demanding handling conditions.

What PP is known for in pallet applications

PP (polypropylene) is stronger and more rigid than HDPE in many pallet designs. It also has strong resistance to harsh solvents, acids, and bases.If chemical exposure is frequent, PP can be the cleaner technical match.

HDPE vs PP—A Simple, Reader-Friendly Comparison

Most buyers do not need a deep polymer lecture. You just need a clear idea of what changes in real handling and environment exposure.

Here is a simple way to compare HDPE pallets and PP plastic pallets without overthinking it.

The clearest differences

-

Rigidity: PP is typically more rigid; HDPE often absorbs impact well.

-

Chemical exposure: PP is often stronger against harsh chemicals.

-

Common choice: HDPE is the most widely used resin for plastic pallets.

-

Recycling: Both can support plastic recycling programs when managed correctly.

A compact comparison table

| Item | HDPE pallets | PP plastic pallets |

|---|---|---|

| Best known for | Tough, versatile, stable handling | Higher rigidity, stronger chemical resistance |

| Typical environments | Warehousing, distribution, washdown | Industrial, chemical exposure, harsher cleaning |

| Handling feel | Often more impact-tolerant | Often more rigid under load |

| Sustainability | Strong recyclability pathways | Recyclable with proper streams |

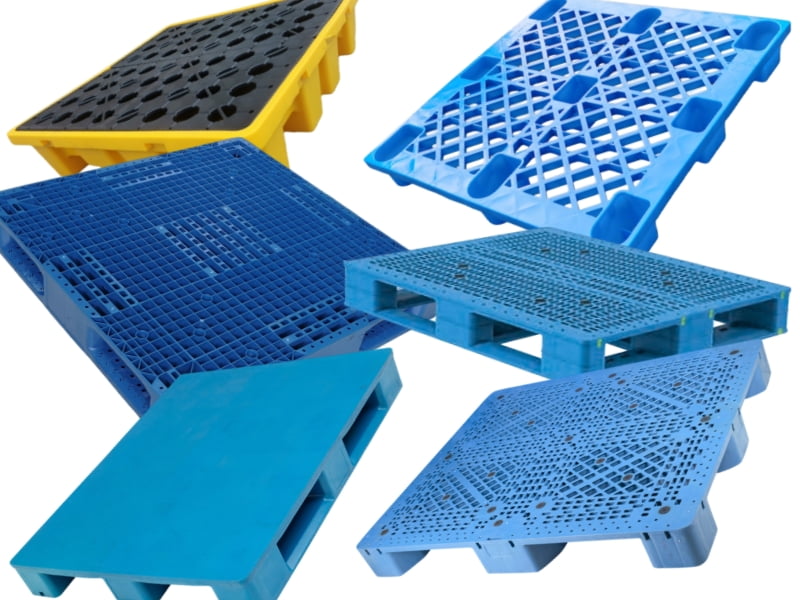

Plastic Pallets—Why More Modern Supply Chains Prefer Them

Plastic pallets are usually selected when you want stable performance and cleaner handling. If you ship repeatedly, consistency becomes a serious advantage.

Many operations move to plastic pallets when they want fewer surprises in handling, cleaning, and export readiness.

The core advantages of plastic (plain and practical)

Plastic pallets keep a more consistent size and weight, so handling feels predictable shift after shift. That helps when pallets touch conveyors, racking, or automated systems.

They also resist moisture, pests, and many chemicals, and they are easier to wash and sanitize, which supports tighter hygiene routines.

Where plastic pallets are commonly used

You will often see plastic pallets in grocery distribution, automotive manufacturing, and automated warehouses. They are also common in food, beverage, and pharmaceutical environments where cleaning standards are higher.

Plastic pallets are usually treated as a reusable asset, so the initial price can be higher than basic wood. The value comes from longer use life and more stable day-to-day performance.

Wood Pallets—The Traditional Standard

Wood pallets are still the baseline in many markets. If your supply chain is mixed and cost is the first filter, wood often shows up first.

What wood pallets are made from

Wood pallets are typically built from hardwood or softwood. The species affects weight, nail holding, and how the pallet reacts to impact and humidity.

In pallet production, the wood choice is also tied to local availability, so quality can vary by region and supplier.

Common structural formats

Most wood pallets fall into two formats: stringer and block. This matters because it changes forklift entry and how the load spreads through the base.

If your team uses different forklifts across sites, structure can matter as much as the wood itself.

Why wood is still widely used

Wood is easy to source, easy to repair, and easy to customize. For many one-way shipments, that practicality keeps it popular.

It also fits well when you do not need strict hygiene control or tight dimensional repeatability.

Natural constraints

Wood needs routine checks for cracks, splinters, and moisture damage. Over time, that can affect safety and handling stability.

Other Pallet Materials —Where They Still Make Sense and Trade-Offs

These pallet materials can be useful in specific cases. Still, plastic pallets are often preferred when you want repeatability, hygiene control, and clean export execution.

Wood composite & presswood pallets

Presswood pallets are molded from wood fiber, and they are often used for export shipping. They can be dimensionally consistent and are commonly positioned as ISPM 15 friendly.

The trade-off is that they are not a universal warehouse pallet, especially when certain stacking or base requirements are needed.

Paper & corrugated pallets

Paper pallets are lightweight and often used for one-way shipping and air freight, where weight matters. They can also support recycling goals in the right system.

The key trade-off is lower strength and moisture sensitivity, even with modern improvements.

Metal pallets (steel&aluminum)

Metal pallets are extremely durable and fire-resistant, and they are easy to clean. They are used in heavy-load or specialized industrial environments.

The trade-off is price, and steel can be heavy and may require corrosion control depending on use.

Polyolefin (PO) pallets

Some PO pallets use blended materials to target cost and rigidity. They can be positioned for dry environments with stable handling needs.

The trade-off is that performance can be more sensitive to blend design, and brittleness can be a concern in some conditions.

Fiberglass pallets

Fiberglass pallets are selected for niche needs like fire performance and high load capacity. In some regulated environments, that can justify the premium.

The trade-off is higher cost and a smaller supply base, since production is more complex.

Composite pallets (blended materials)

Composite pallets can mix plastics with fibers or reinforcements to improve stiffness while keeping moisture resistance. They can work well when a spec demands a targeted balance.

The trade-off is that results depend heavily on the exact recipe, so consistent manufacturing control matters.

Final Takeaway: Choose the Right Pallet Material With Confidence—Backed by CN Plast Plastic Pallet Manufacturing

By now, the picture should feel clearer, not more complicated. Wood pallets still work for basic circulation, while plastic pallets bring the stability that modern operations demand—especially when hygiene, repeat handling, and export consistency matter. In most real-world cases, the decision comes down to two reliable workhorses: HDPE pallets for versatile daily logistics, and PP plastic when higher rigidity and stronger chemical resistance are required. When pallet materials are understood this way, you stop guessing—and start specifying with control.

CN Plast operates as a plastic pallet manufacturer with a production mindset built around repeatable performance: stable dimensions, consistent load behavior. That means your pallet selection becomes easier, your handling becomes more predictable, and your team spends less time dealing with avoidable pallet-related interruptions. This is exactly the kind of clarity procurement teams need—simple, technical enough to trust, and directly usable in real purchasing conversations.

Ready to Specify Your Plastic Pallets? Send Your Requirements and Get a Fast Recommendation

Stop wasting cycles on “maybe this works.” Send your load target, pallet size, handling method (forklift/conveyor/racking), and working environment (wet washdown or chemical exposure)—and get a clear recommendation on HDPE vs PP, plus the right structure for your workflow.