Pallet materials encompass five main categories: wood, plastic, metal, composite, and paper/corrugated pallets, each offering distinct performance characteristics that you need to match with your operational requirements. Your choice directly impacts your warehouse efficiency, shipping costs, and regulatory compliance across your entire supply chain.

This article will conduct an assessment of each material category in terms of structural performance and compliance, in order to help you gain a better understanding of pallets.

Wood Pallets: When Are They the Best Choice?

Wood pallets remain the global standard because they balance performance, cost, and repairability better than alternatives in most applications.Think about what you see every day in your operation—wood pallets dominate the global market for good reason. They’re strong, repairable, and cost-effective for most applications. But when your shipments cross borders, ISPM 15 compliance can add steps, paperwork, and timing risks that complicate export planning.

Advantages of Wood Pallets

Wood offers exceptional strength-to-weight ratios. A standard 48×40-inch wood pallet weighs 35-45 pounds but handles 4,000+ pounds safely. This efficiency keeps shipping costs manageable.

Availability and recycling create practical advantages. Wood pallets are manufactured globally and easily recycled into mulch, biomass fuel, or particle board when damaged beyond repair.

Wood Pallet Limitations and Export Compliance

Wood’s organic nature creates challenges you must consider. Moisture absorption causes dimensional changes and weight increases.

ISPM 15 compliance complicates international shipping. Wood pallets need heat treatment or methyl bromide fumigation to prevent pest transmission. Non-compliant shipments face rejection or costly delays at borders.

Pest and contamination risks concern food and pharmaceutical industries. Wood can harbor insects, fungi, or bacteria that plastic and metal materials resist naturally.

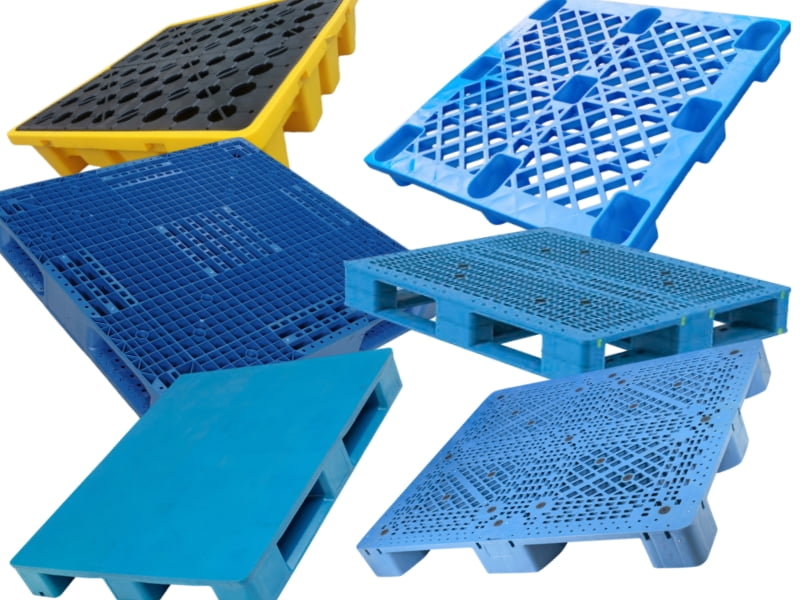

Plastic Pallets: HDPE vs PP and When to Choose Them

Plastic pallets come in two main types: HDPE (high-density polyethylene) and PP (polypropylene). They excel in hygiene-critical environments like food processing and pharmaceuticals. You’ll pay more upfront, but they last longer and maintain consistent dimensions.

HDPE Plastic Pallets

High-density polyethylene creates the strongest plastic pallets available. HDPE resists impacts, chemicals, and temperature extremes from -40°F to 180°F without cracking or warping.

Hygiene benefits make HDPE ideal for food, beverage, and pharmaceutical applications. The non-porous surface prevents bacterial growth and withstands pressure washing with hot water and sanitizers.

Dimensional consistency matters for automated systems. HDPE pallets maintain tolerances within 1/8 inch, ensuring smooth operation through conveyor systems, robotic handlers, and automated storage.

HDPE pallets typically weigh 35-65 pounds and last 10+ years with proper handling, making them cost-effective for closed-loop systems.

Common HDPE applications span industries requiring maximum durability and hygiene. Food processing facilities use HDPE for dairy products, meat processing, and beverage production where sanitization is critical. Pharmaceutical companies rely on HDPE for drug manufacturing and medical device assembly. Chemical industries choose HDPE for resistance to acids, bases, and solvents that would damage other materials.

Polypropylene (PP) Plastic Pallets

Polypropylene offers a lighter alternative to HDPE. PP pallets weigh 20-40 pounds while maintaining good strength for medium-duty applications.

Temperature resistance gives PP advantages in extreme conditions. It stays flexible at lower temperatures than HDPE and handles heat up to 200°F without deformation.

Chemical compatibility makes PP suitable for specific applications where HDPE might react. PP resists stress cracking from certain chemicals and maintains flexibility under repeated loading cycles.

PP works well for export shipping where you won’t recover pallets. The lighter weight reduces freight costs compared to heavier plastic options.

Typical PP applications focus on lighter-duty operations and specialized environments. Electronics manufacturers use PP for component shipping where anti-static properties and light weight matter. Retail distribution centers choose PP for consumer goods that don’t require maximum strength. Cold storage facilities rely on PP’s low-temperature flexibility for frozen food handling.

When Should You Choose Metal, Paper, or Composite Pallet Materials?

Beyond wood and plastic, three specialized materials serve unique applications where standard options can’t meet specific performance requirements.

Steel Pallets for Heavy-Duty Applications

Maximum load capacity defines steel’s role. Steel pallets handle 10,000+ pounds safely – far beyond wood (4,000 lbs) or plastic (6,000 lbs) limits.

Extreme durability justifies steel’s higher cost in punishing environments. Steel pallets last decades with minimal maintenance, while wood or plastic would fail quickly under heavy industrial use.

Industries requiring steel include:

- Heavy machinery manufacturing

- Steel and metal processing

- Chemical and petroleum

- Military and defense applications

Steel’s major drawbacks limit broader adoption. Weight becomes problematic – steel pallets weigh 70-100 pounds, dramatically increasing shipping costs. Corrosion attacks steel in humid or marine environments unless expensive coatings are applied. The high cost means steel pallets often cost 5-10 times more than wood alternatives.

Paper and Corrugated Pallets: When Lightweight Matters Most

Export shipping advantages drive paper pallet adoption. They’re exempt from ISPM 15 requirements, eliminating heat treatment costs and border delays that affect wood pallets.

Weight savings directly reduce shipping costs. Paper pallets weigh 10-15 pounds versus 35-45 pounds for wood. On air freight, this difference saves significant money in shipping fees.

Critical limitations restrict paper pallet use significantly. Load capacity tops out at 2,000-3,000 pounds maximum. Moisture destroys paper pallets – they can’t handle rain, humidity, or wet products. Single-use design means you can’t recover investment through reuse. Rough handling tears paper pallets easily, making them unsuitable for industrial environments.

Composite Pallets: Engineered Solutions for Specific Problems

Wood-plastic composites blend wood fiber with recycled plastic resins. This combination provides wood’s strength and workability with plastic’s moisture resistance and dimensional stability.

Metal-plastic hybrids use steel reinforcement frames with plastic deck surfaces. You get metal’s strength where needed while plastic provides hygiene benefits and lighter weight.

Composite disadvantages include high cost and limited availability. These pallets often cost more than premium plastic options while offering performance that may not justify the expense. Repair becomes difficult or impossible when different materials are bonded together. Limited supplier base means longer lead times and fewer sourcing options.

Plastic pallets differ in more than just materials. For more pallet types, please read the article: Types of Pallets: A Complete Guide to Sizes, Materials & Structures

What Happens When You Choose the Wrong Pallet Material?

Here’s the reality—your pallet selection mistakes can cascade through your entire supply chain, creating costly operational disruptions you might not anticipate. When you choose wood pallets for pharmaceutical shipments, you’re essentially risking contamination issues and regulatory violations that could shut down your operations overnight.

Using pallets beyond their weight capacity leads to structural failure during transport. You’ll face damaged goods, insurance claims, and customer relationships that take months to rebuild. Your cost savings from cheaper materials quickly disappear when forklifts crack overloaded pallets—trust me on this one.

Export delays become inevitable when you select non-compliant materials. Wood pallets without ISPM 15 treatment get rejected at customs, leaving your time-sensitive shipments stranded at the border. You’ll absorb detention fees, expedited shipping costs, and contract penalties that far exceed any initial material savings—it’s a costly lesson.

Temperature-sensitive applications demand material stability you simply can’t compromise on. Metal pallets in freezer environments create condensation problems. Your cold chain integrity depends on matching material properties to environmental conditions—no exceptions here.

Choose corrugated pallets for heavy machinery, and you’re practically guaranteeing product damage and safety hazards. Your warehouse team faces injury risks from collapsed loads, while your insurance premiums increase due to preventable accidents. Understanding each material’s limitations protects both your operations and your bottom line.

What Hygiene Standards Must Your Pallets Meet in Food, Pharmaceutical, and Clean Environments?

Industries with strict hygiene standards face limited material choices – contamination risks can shut down operations or trigger costly recalls.

Material Selection for Regulated Industries

FDA-approved materials include specific plastic resins, aluminum, and treated wood. Recycled plastics often lack food-grade certification, limiting your options to virgin material pallets.

Plastic pallets dominate hygienic applications for good reasons. HDPE and food-grade PP offer non-porous surfaces that prevent bacterial colonization – a critical advantage over wood’s fibrous structure. The smooth, sealed surface allows thorough cleaning with high-pressure washers, hot water up to 180°F, and aggressive sanitizing chemicals that would damage other materials.

Chemical resistance makes plastic ideal for sanitization protocols. HDPE withstands quaternary ammonium compounds, chlorine bleach solutions, and acid-based sanitizers without degradation. This durability ensures pallets maintain their hygienic properties through hundreds of cleaning cycles.

Temperature cycling during wash-down operations doesn’t affect quality plastic pallets. They handle rapid temperature changes from freezer storage (-10°F) to hot wash cycles (160°F+) without cracking or warping that could create contamination harboring points.

Contamination prevention demands smooth surfaces without cracks, splinters, or porous areas. Wood’s natural grain and potential for splintering creates countless microscopic hiding places for pathogens. Even treated wood can absorb liquids and odors that persist through cleaning attempts.

Metal options like aluminum provide excellent hygiene properties but create practical challenges. While aluminum resists corrosion and cleans easily, its weight and cost limit adoption primarily to specialized pharmaceutical or medical device manufacturing where the benefits justify the investment.

Pharmaceutical and Medical Device Applications

GMP compliance requires validated cleaning procedures and materials that don’t shed particles or absorb contaminants. This eliminates wood entirely and limits plastic choices to specific pharmaceutical-grade resins with documented purity levels.

Cleanroom compatibility means materials can’t generate dust, fibers, or static electricity. Aluminum and specific anti-static plastic formulations meet these stringent requirements for sterile manufacturing environments.

Traceability requirements often mandate serialized pallets with tracking systems. Plastic and metal pallets accept permanent laser marking or embedded RFID tags better than wood, enabling lot tracking through the supply chain.

Cross-contamination prevention requires dedicated pallet pools for different product categories. Plastic pallets’ durability and marking capability make this segregation practical, while wood’s shorter lifespan makes dedicated pools economically challenging.

The combination of cleanability, durability, and marking capability makes plastic pallets the preferred choice for most regulated industries, despite higher initial investment compared to wood alternatives.

What Is ISPM 15 and How Do International Regulations Affect Export Compliance?

International shipping regulations can make or break your export business – non-compliance means rejected shipments and angry customers.

What Is ISPM 15 and Why It Matters

ISPM 15 (International Standards for Phytosanitary Measures No. 15) requires wood packaging treatment to prevent pest transmission between countries. Over 100 countries enforce these rules.

Heat treatment raises wood core temperature to 56°C for 30 minutes minimum. Treated pallets receive official stamps showing treatment method, date, and facility certification.

Certification requirements mean you can’t use unmarked wood pallets for most exports. Treatment adds costs and potential delays if documentation is incomplete.

Rejection consequences include shipment holds, re-treatment costs, return shipping, and customer penalties. A single non-compliant container can result in substantial delays and fees.

Alternatives to Wood for Export Shipping

Plastic Pallets: The Premium Export Solution

Complete ISPM 15 exemption makes plastic pallets the most straightforward export option. Since they’re manufactured rather than harvested, they carry no pest transmission risk and require zero treatment documentation.

Multi-trip economics favor plastic for established export routes. While initial investment is higher, the elimination of per-shipment treatment costs, reduced administrative overhead, and zero rejection risk often justify the investment for regular exporters.

Temperature and moisture stability provides additional benefits in international shipping. Unlike wood, plastic pallets don’t absorb moisture during ocean transport or expand/contract with temperature changes in different climates, maintaining consistent dimensions and performance.

Cleanability between shipments allows plastic pallets to meet various countries’ agricultural inspection requirements. They can be easily sanitized between loads, reducing contamination risks that might trigger additional inspections.

Metal and Alternative Material Options

Aluminum and steel pallets share plastic’s ISPM 15 exemption while offering extreme durability for heavy export loads. However, their weight impacts freight costs and handling requirements limit adoption to specialized applications.

Paper and pressed wood alternatives provide cost-effective solutions for one-way export shipments. These engineered materials avoid ISPM 15 requirements while offering lighter weight than traditional wood, reducing overall shipping costs for air freight or weight-sensitive applications.

Composite materials blend various fibers and resins to create ISPM 15-exempt pallets with performance characteristics between wood and plastic, though availability and standardization remain limited compared to traditional options.

Common Questions About Pallet Materials

Understanding key specifications helps you make informed decisions and avoid costly mistakes in material selection.

Weight and Load Capacity Comparisons

Material density differences directly affect shipping costs.

- Wood: 35-45 lbs;

- Plastic: 35-65 lbs;

- Steel: 70-100 lbs;

- Aluminum: 40-60 lbs;

- Paper: 10-15 lbs.

Load rating standards use uniform test methods. Static load = stationary warehouse storage. Dynamic load = forklift handling. Racking load = supported only at edges.

Safety factor considerations prevent failures. Industry standard requires 40% safety margin above expected loads. A 2,000-lb product needs 2,800-lb dynamic rating minimum.

Never exceed manufacturer ratings – liability insurance may not cover failures from overloading pallets beyond published specifications.

Lifespan and Maintenance Requirements

Expected service life varies by material and application:

- Wood: 3-5 years typical, 10-15 trips average

- Plastic: 10+ years, 100+ trips possible

- Steel: 15-20 years with maintenance

- Aluminum: 20+ years, minimal maintenance

- Paper: Single-use only

Compliance and Certification Issues

Industry-specific requirements vary significantly. Pharmaceuticals need GMP validation. Food requires FDA approval. Automotive demands specific dimensional tolerances.

Quality standards include ISO, EPAL, and GMA specifications. These standards ensure consistent quality and interchangeability between suppliers and users.

Documentation needs increase with application criticality. Export shipments need ISPM 15 certificates. Medical devices require material certifications and traceability records.

Maintain compliance records for audits – regulatory violations can result in facility shutdowns, product recalls, or import/export license suspension.

Making the Right Choice: Your Path to Optimized Pallet Operations

The pallet material decision you’re facing isn’t just about immediate costs – it’s about building a foundation for operational efficiency, regulatory compliance, and long-term profitability. You now have the framework to evaluate each option against your specific requirements, from load capacity and durability to export compliance and sustainability goals.

Your competitive advantage lies in making informed decisions while others rely on assumptions. Companies that align pallet selection with actual operational needs consistently outperform those making decisions based solely on upfront costs. Whether you choose wood for its versatility, plastic for its durability, or metal for specialized applications, you’re now equipped to calculate true total cost of ownership and avoid costly mistakes.

Ready to optimize your pallet operations? At CN Plast, we specialize in manufacturing high-quality plastic pallets that solve the exact challenges outlined in this guide – from ISPM 15 compliance to sustainability requirements and total cost optimization.

Don’t let pallet problems disrupt your operations. Our engineering team can evaluate your specific load requirements, usage patterns, and operational constraints to recommend the optimal plastic pallet solution. We’ll help you calculate true ROI and eliminate the guesswork from your material selection process.

Contact our technical specialists today for a customized assessment – because the right pallet decision made now prevents costly operational problems later. Your supply chain efficiency depends on it.