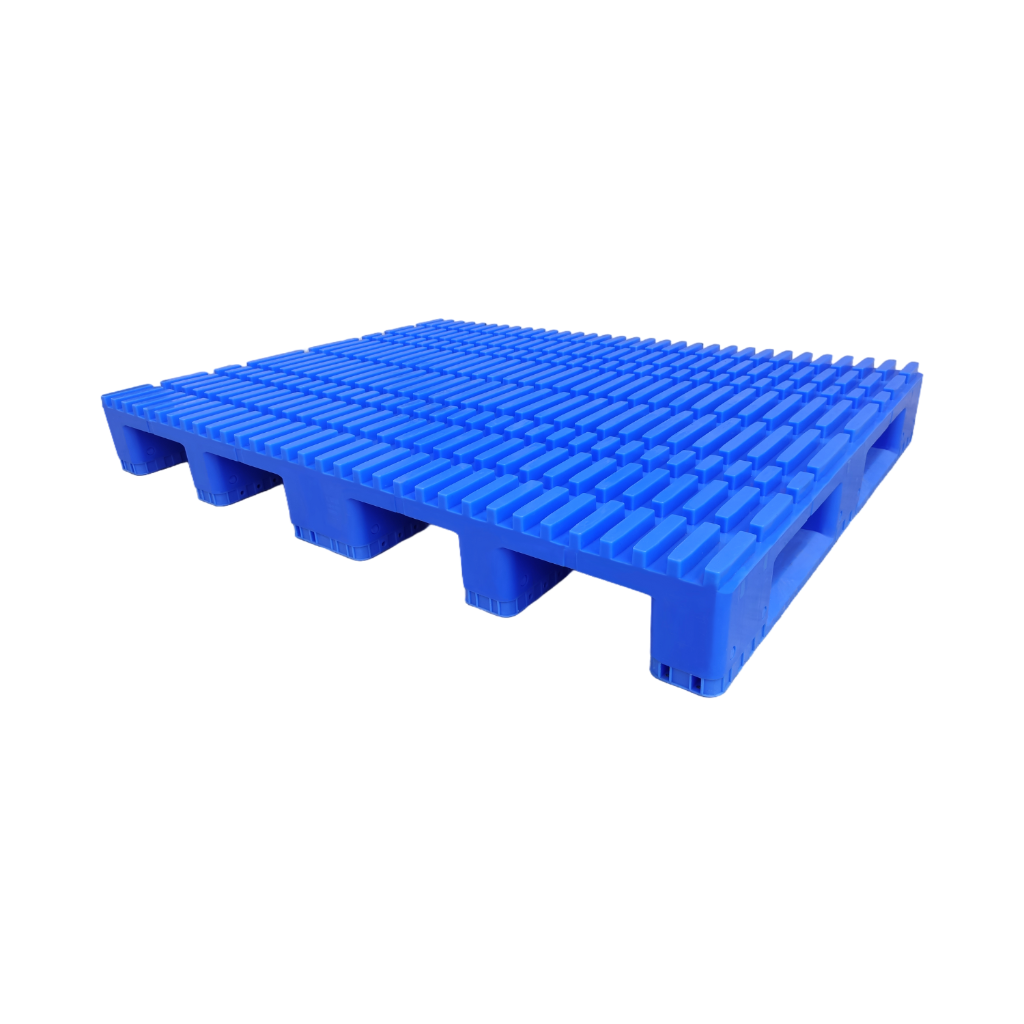

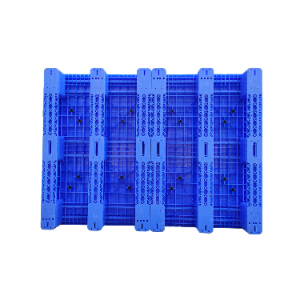

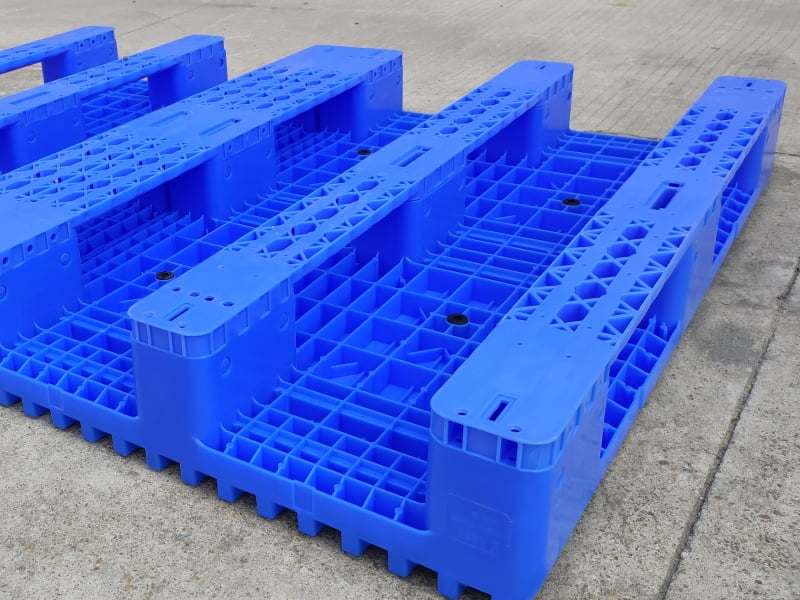

Plastic Pallet for Printing – Slotted Top | ENL-1612-190

The ENL-1612-190 Printing Plastic Pallet is engineered with high-density HDPE for KBA and compatible printing equipment. The 1600mm × 1200mm dimensions perfectly match A0 paper format (841mm × 1189mm), while the slotted top deck enables seamless automatic feeding. 4-way forklift entry ensures efficient handling, supporting dynamic loads up to 2000kg and static loads up to 5000kg. Certified to ISO 9001, SGS, and international standards, this pallet is backed by our 20+ years of expertise and 15-day lead time to keep your printing production running smoothly.

Logistics Data

Printing Pallet Specifications

CNplast is considered the most trusted manufacturer of Printing Pallet in China

Technical Data

| Model | ENL-1612-190 |

| Usage | Suitable for most printing equipment operations |

| Material | HDPE; PP |

| Processes | Injection Molding |

| Diameter Size | 1600mm × 1200mm × 190mm |

| Compatible Printer Models | KBA: RAPIDA141,142.162 |

| Compatible Press Format | Full Sheet |

| Dynamic Load Capacity | 2000kg |

| Static Load Capacity | 5000kg |

| Usage Temperature | -30℃ to 40℃ |

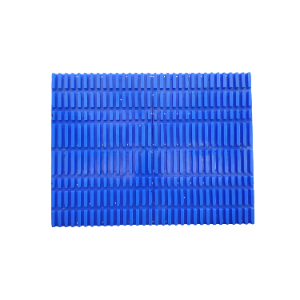

| Deck | Groove Deck |

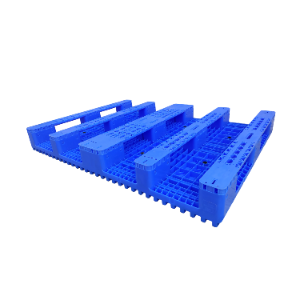

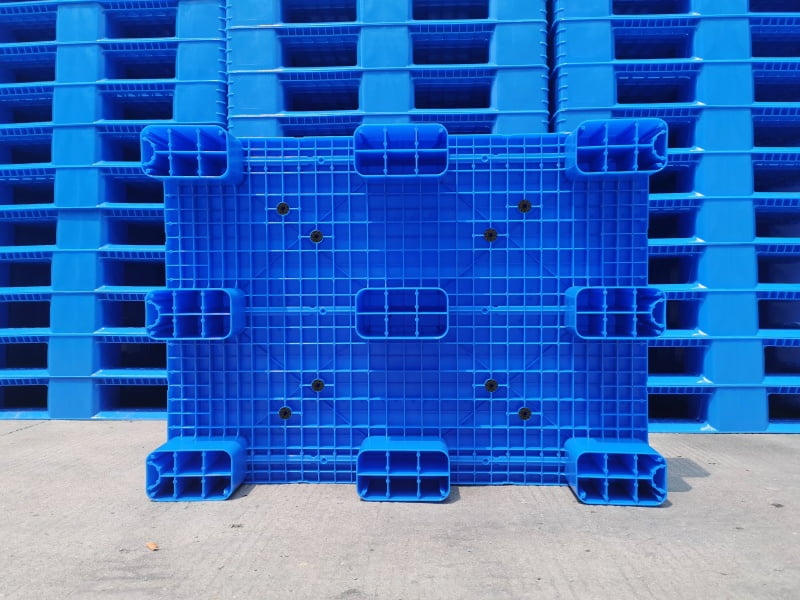

| Base | Multiple Legs |

Handling Data

| Forklift | 4 Way Entry |

| Pallet Jack | 4 Way Entry |

| Stackable | Yes |

| Nestable | No |

| Reusable | Yes |

| Color | Yellow, Blue, Red, Green, Black, Orange, Grey, White, Custom |

| Logo / Printing | Screen / Pad / Heat Transfer / Emboss / Molded-In |

Features of Printing Pallet

Advanced engineering and innovative design features for superior performance in printing industry applications

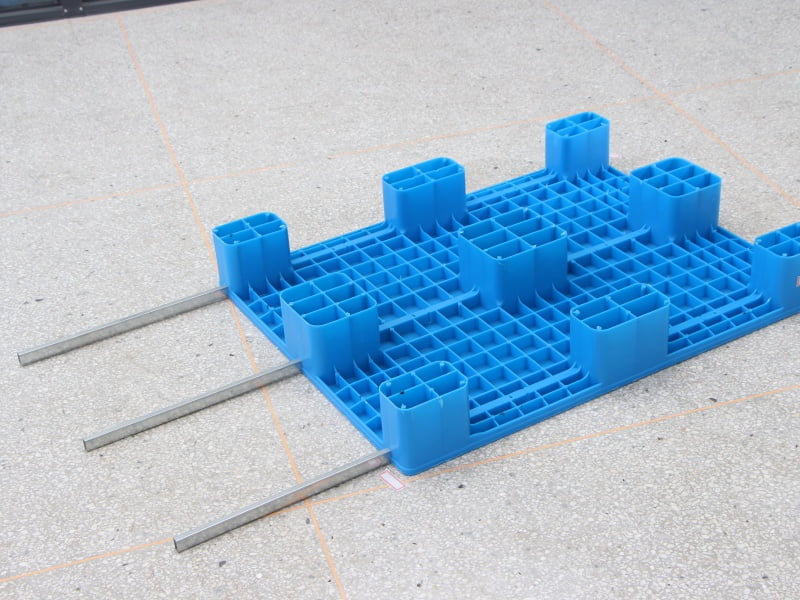

Built-in Steel Reinforcement

Our printing plastic pallets feature integrated steel tube reinforcement for superior strength and durability in demanding industrial environments.

- • Enhanced load-bearing capacity for heavy printing materials and equipment

- • Improved structural integrity to prevent warping and deformation

- • Extended service life reducing replacement costs and downtime

Anti-slip Bottom Design

The specially engineered anti-slip bottom surface ensures maximum stability and safety during material handling and transportation operations.

- • Textured surface pattern provides excellent grip on various floor types

- • Reduces sliding risk during forklift operations and manual handling

- • Maintains stability even in wet or oily industrial environments

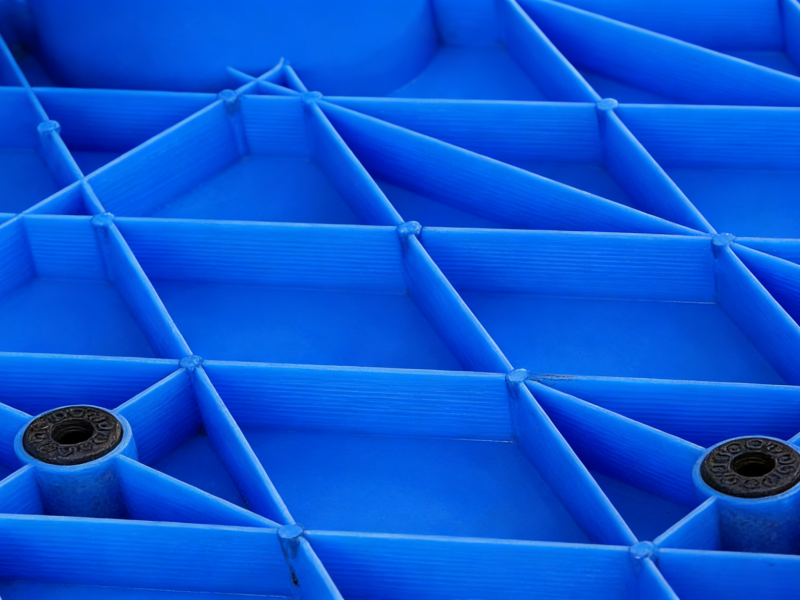

Reinforced Bottom Structure

Advanced ribbing design strengthens the pallet base structure, delivering exceptional performance under heavy loads and repeated use.

- • Strategic reinforcement ribs distribute weight evenly across the pallet

- • Prevents bottom flexing and maintains dimensional stability

- • Optimized rib placement maximizes strength while minimizing material usage

RFID-Ready Card Slot with Cover

Integrated RFID card slot with protective cover enables advanced inventory tracking and automated warehouse management systems.

- • Weatherproof cover protects RFID cards from moisture and damage

- • Compatible with standard industrial RFID tracking systems

- • Enables real-time inventory monitoring and supply chain visibility

Customization Options

Tailor your plastic pallets to meet your specific requirements and brand identity

Custom Colors

Match your brand colors with unlimited color options available

Logo Printing

Add your company logo for enhanced brand visibility and recognition

Custom Molds

Develop unique molds to create pallets perfectly fitted to your needs

Size Variations

Multiple size options to fit different applications and requirements

Custom Load Capacity

Enhance pallet load capacity with added reinforcement for heavier loads

Related Products

Explore our other high-quality Plastic Pallets for Printing

Printing Plastic Pallet – Slotted Top | ENL1050760-175

Diameter Size: 1050mm × 760mm × 175mm

Plastic Pallet for Printing – Flat Top - 7 Legs - Nestable | ENL8060-140

Diameter Size: 800mm × 600mm × 140mm

Plastic Pallet for Printing – Slotted Top - 9 Legs | ENL8065-145

Diameter Size: 800mm × 650mm × 145mm