A pallet load usually doesn’t fail because of one dramatic mistake. It fails because small issues—an imperfect pallet, uneven weight, hidden voids, low friction on a plastic deck, or wrap that isn’t anchored—build up at every forklift move and every mile in transit. This guide shows a simple, repeatable method for pallet loading: how to inspect pallets, build square layers from bottom to top, choose the right stacking pattern, and secure the unit so it stays tight through multiple touchpoints. You’ll also get clear working load ranges for different pallet base designs, plus friction controls that prevent “load walking” on plastic pallets. If you want fewer claims and a SOP your team can follow without guesswork, read on.

Are You Ready to Load, or Are You About to Build in Risk?

Confirm the pallet is serviceable

Before you load pallets, check the pallet like you check the product. A small crack or a warped deck can turn stable pallet loads into damage after one hard stop.

Look for cracks, broken runners/legs, deck bowing, and damaged fork entries. If it rocks on the floor, do not use it.

Confirm cleanliness when shipping food, pharma, or sensitive packaging

If your customer audits hygiene, the pallet must be clean and dry. Dirt and oil also reduce friction, so loaded pallets can slide even when the wrap looks tight.

Use a simple rule: no visible residue, no odor, no sticky areas. In wet zones, let the deck dry before staging.

Confirm the packaging can survive compression and handling

Your wrap cannot “fix” weak cartons. If cases crush or bulge, your pallet configuration for building materials and other dense goods will lose shape fast.

Check carton strength, tape quality, and closure method. Make sure inner packs cannot move inside the case, or the load will settle and create voids.

Confirm weight limits and the distribution plan

Weight is not only the total number. It is where that weight sits. If you exceed the dynamic load rating, the first forklift move can start the failure.

Confirm gross weight, then plan the layout before stacking. Balanced weight improves pallet stabilization and reduces stress points.

How Do You Build a Stable Load from the First Layer to the Top?

Control center of gravity and balance

You want a low, centered load. That is what protects you during turns, braking, and dock impacts.

Put heavy cases on the bottom. Keep left/right weight even. If one side feels denser, correct it early.

Keep the load “square” with consistent layers

A square load wraps better and moves better. Uneven layers create weak edges, and the wrap loses hold during vibration.

Keep each layer flat. Align case edges so the stack stays straight from bottom to top.

What Is the Safe Pallet Load Weight for Forklift Handling?

Set weight limits for real handling, not “best-case” storage

Your load can be “within weight” and still fail if the pallet is moved, turned, or stopped repeatedly. For pallet loading, your working limit should follow dynamic load (forklift handling), not static load (floor storage).

Set one clear SOP weight rule your operators can follow, and keep it linked to your us pallet size and loading height practices so the whole team builds consistent pallet loads.

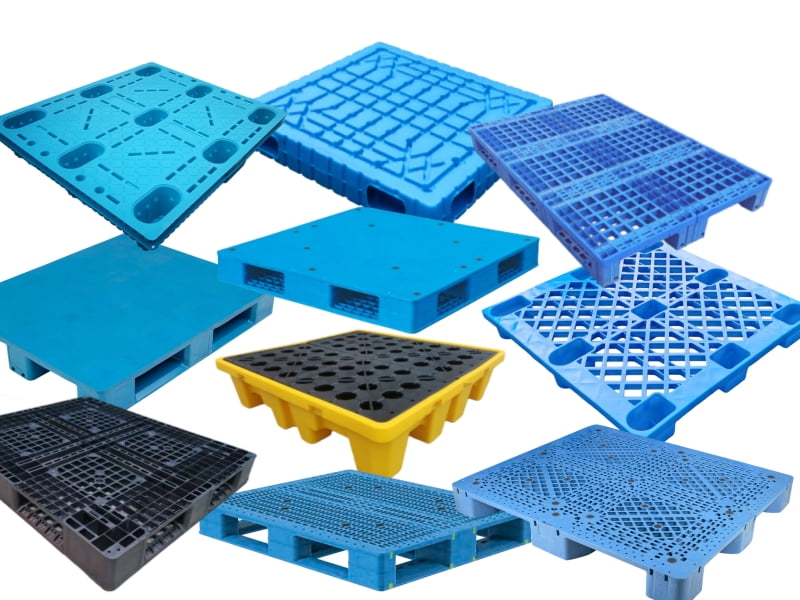

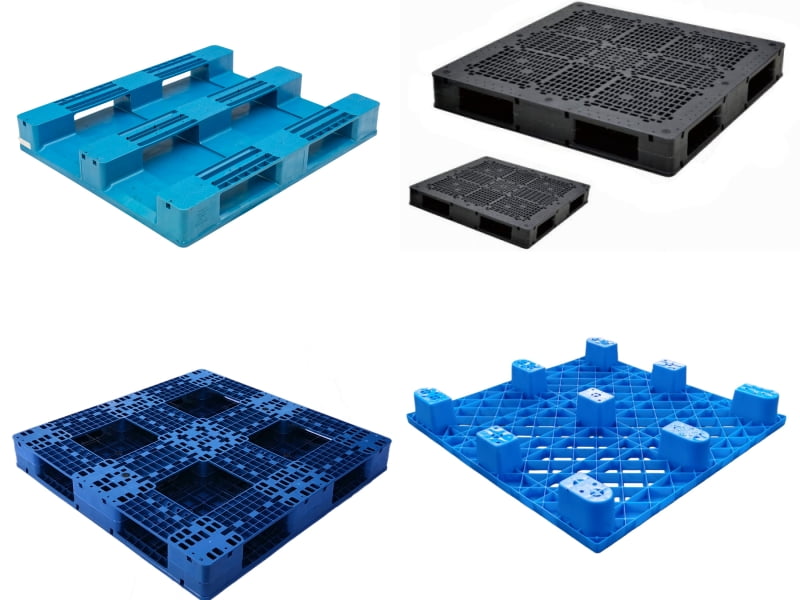

Use practical load ranges by pallet base design

Different base designs carry weight differently during movement. Use these ranges as a buyer-friendly reference when you load pallets, then confirm with your supplier’s test data for your exact model.

| Pallet Base Design | Typical Use Case | Static Load (on floor) | Dynamic Load (forklift moves) |

| 3-runner / reversible / 6-runner pallets (common heavy-duty styles) | Heavy-duty storage and repeated handling | 4–6 tons | 1–2 tons |

| 9-leg (nestable export-style pallets) | Export lanes where space efficiency matters | 2–4 tons | 0.5–1 ton |

Match the load limit to lane risk and handling frequency

Even when you stay inside the numbers, risk changes by lane. Export and long-haul routes add vibration and more touchpoints, so weak pallet loads loosen faster.

If your pallet loaded unit is mixed-SKU, high value, or handled many times, apply a stricter dynamic limit and upgrade control: better wrap anchoring, strapping when needed, and friction layers to reduce slip.

How Do You Prevent a Wrapped Pallet from Loosening During Shipping?

Wrap to lock cartons, then lock to the pallet

Stretch film must do two jobs: make cartons one unit, then anchor that unit to the pallet deck. If the base is not captured, the first layer can walk.

Wrap from low to high with strong base coverage. Finish by anchoring film around the pallet edges.

Add strapping when the lane is tough

Strapping is a control step for harsh handling, long-haul vibration, and high-value cargo. It helps when film tension drops over time.

Use corner/edge protection so straps do not crush cartons. Then tension straps to hold the unit, not to damage packaging.

Build for repeat handling

Most pallet loading failures happen after several moves, not the first lift. Your load must survive staging, trailer loading, sorting, and delivery.

Do a “first-move recheck” after you move the pallet once. If it shifts early, it will shift more later.

Why Do Loads Slip More Easily on Plastic Pallets—and How Do You Control Friction?

Know what reduces friction

Plastic decks can be smooth. Slip risk rises with glossy cartons, dust, moisture, and cold-room condensation. Vibration then turns small slip into major shift.

Look at your real lane conditions: wet floors, humidity, freezer-to-ambient moves, and long truck routes.

Use friction tools that stop base-layer movement

If the first layer moves, the whole unit loses control. Anti-slip sheets or friction mats under the first layer often solve this fast.

If available, specify non-slip deck options such as texture or anti-slip strips. Combine friction control with correct wrapping.

Make friction control a buying spec

Friction should not depend on operator “feel.” You need repeatable performance across shifts and sites.

Define your lane (cold room, export, wet zones, long-haul). Ask your supplier for the recommended interface materials and the limits for safe use.

What If the Load Is Mixed, Partial, or Irregular—How Do You Avoid Failure Points?

Mixed-SKU and partial pallets

Mixed cases fail when weight zones are scattered. Your goal is to reduce twisting and keep dense weight supported.

Group heavy SKUs together and keep them low. Avoid single-point loading that concentrates stress on one deck spot.

Irregular or fragile loads

Fragile items fail on edges first. Irregular items create gaps that grow in transit. You need a layout that protects weak packs and removes movement.

Place fragile goods toward the center. Add protective packaging. Increase securing intensity with tighter wrap control and strapping when needed.

Can Your Supplier Prove Compliance and Quality—Fast and Clearly?

Certifications that support supplier approval

Certifications do not replace performance, but they show process control and reduce audit burden. If you run vendor approval, this saves time.

Ask for ISO 9001 and confirm the scope matches the factory making your pallets. Check validity and date, not just the logo.

Material compliance for regulated lanes

If you ship food, pharma, or sensitive chemicals, material proof is part of the purchase. You should be able to confirm HDPE/PP grade and virgin vs recycled content.

Request a material declaration and market-specific compliance statements that match where you ship.

Testing evidence you should request

Testing should answer one question: will your pallet loads stay stable under your handling and lane conditions? The best suppliers provide results that are easy to compare.

Request load performance checks (static/dynamic, stacking, and racking if relevant). Ask for impact/drop checks if handling is rough, and temperature suitability for cold rooms or outdoor use.

Build Stable Pallet Loads That Arrive Intact—Powered by CN Plast Plastic Pallets Manufacturers

You now have a repeatable way to keep pallet loads stable in real shipping: start with a sound pallet, build a square load with no voids, control weight distribution, secure the unit with the right wrap/strapping, and add friction control when plastic decks and smooth cartons raise slip risk. Most damage is not random—it is small movement that grows at every touchpoint. When your team follows one clear pallet loading SOP, you reduce claims, protect delivery performance, and gain tighter control over cost.

As experienced plastic pallets manufacturers, CN Plast supplies pallets engineered for stable handling and predictable performance. Tell us your product type, total weight, stacking method, and route conditions (export, cold room, long-haul). We will recommend the right CN Plast pallet model and load rating for your operation, and provide a simple loading and stabilization guide—so you purchase with clarity and ship with confidence.