World-Class Manufacturing Capabilities

With over 25 years of experience, we proudly operate two fully automated factories, 60 production lines, and more than 700 injection molds. Our dedicated engineering team designs custom pallets and introduces hundreds of new models annually, ensuring continuous innovation and meeting your specific requirements.

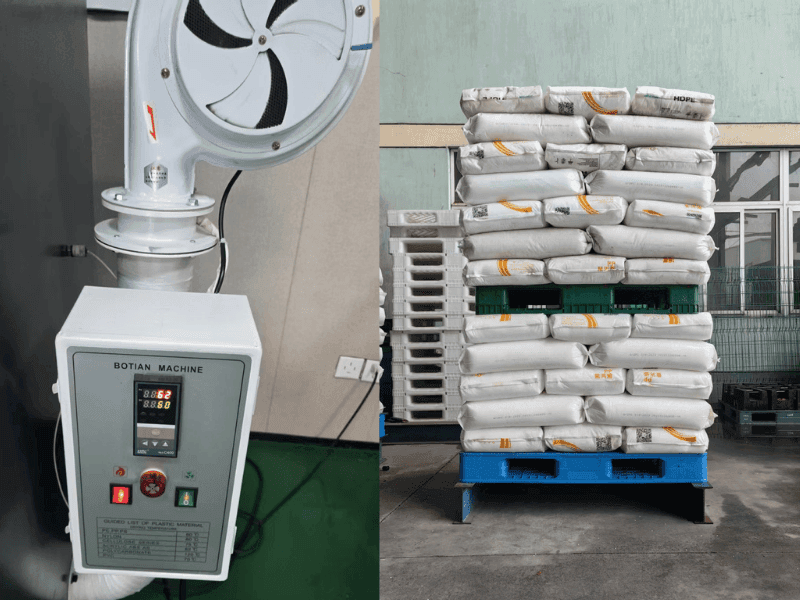

Injection Machines

State-of-the-art automated injection molding equipment

Precision Control

Ultra-precise manufacturing with minimal tolerance

Quality Inspection

Comprehensive testing on every single product

Pallets Manufacturing Capabilities

Injection Molding Manufacturing

At CNplast, we use advanced injection molding technology to produce high-quality, cost-effective plastic pallets with superior precision, strength, and customized designs.

High Precision and Durability

Our systems deliver exceptional accuracy, producing pallets that can withstand heavy-duty use without failure.

Customizable Designs

Injection molding allows for complex, custom pallet designs, offering flexibility for unique client needs.

Fast Production and Efficiency

Automated systems ensure swift production times without compromising on quality.

Cost-Effective and Eco-Friendly

Our efficient injection molding processes minimize material waste, providing both cost savings and environmental benefits.

Blow Molding Manufacturing

We also use advanced blow molding technology to produce durable, lightweight, and custom-designed plastic pallets for diverse applications.

Uniform Wall Thickness

Our blow molding process ensures consistent wall thickness, resulting in stronger and more durable pallets.

Lightweight Yet Strong

Blow molding enables the production of lightweight pallets without compromising their strength, making them ideal for efficient handling and storage.

High-Volume Production

This process allows for rapid production, ensuring timely delivery for large orders.

Cost-Efficient Customization

Blow molding allows for a wide range of custom designs at an affordable cost, making it suitable for diverse industry needs.

Rotomolded Molding Manufacturing

Our rotomolded process produces durable, custom-sized, and lightweight plastic pallets with excellent strength and consistency for high-volume applications.

Superior Impact Resistance

Rotational molding ensures pallets are highly impact-resistant, ideal for heavy-duty loads and tough environments.

Uniformity in Structural Integrity

This process creates uniform wall thickness, enhancing strength and stability under extreme conditions.

Customizable and Versatile

Rotational molding offers more design flexibility, enabling intricate shapes and custom pallets for specific needs.

Cost-Effective for Large Volumes

Thicker plastic layers and reinforced design give rotational molding pallets higher load-bearing capacity, ideal for heavy-duty use.

Complete Production Process

Our comprehensive one-stop manufacturing service ensures quality control at every stage of production

Mold Development

Advanced CAD/CAM technology for precision mold design and development.

Material Processing

High-grade materials with RoHS/REACH compliance and rigorous testing.

Injection Molding

Automated process with precise temperature and pressure control.

Cooling & Forming

Controlled cooling for optimal structural integrity and accuracy.

Manual Finishing

Expert craftsmen ensure highest standards of functionality and appearance.

Quality Inspection

Comprehensive quality checks ensuring ISO 9001 standards compliance.

Comprehensive Quality Control

Our multi-stage quality assurance process ensures every product meets international standards, with strict oversight at each stage.

Material Testing

We ensuring materials meet RoHS/REACH, confirming strength & performance

- • Chemical composition analysis

- • Mechanical property testing

- • Environmental compliance check

Production Control

Automated molding with ±0.1mm accuracy ensures consistent quality

- • Real-time parameter monitoring

- • Dimensional accuracy verification

- • Surface quality inspection

Final Inspection

100% factory testing following ISO 9001 protocols to ensure high-quality standards

- • Load capacity testing

- • Visual defect inspection

- • Packaging quality check

Quality Control Team

Our skilled team, with 25+ years of experience, oversees quality at every production stage, ensuring reliability and excellence.

Transform Your Supply Chain Today

Join industry leaders who trust our ISO-certified plastic pallets for their critical operations. Get your custom solution in just 48 hours.

Get In Touch

Direct Line

+8618560616085

Available 24/7 for urgent inquiries

Email Support

sales@cn-plast.com

Response within 2 hours

Manufacturing Hub

Qingdao, Shandong, China

Visit our 75,000 ㎡ facility