Plastic Pallet

Enlightening Pallet, China's top manufacturer of eco-friendly plastic pallets, serves diverse industries with high-quality, durable products.

Enlightening Pallet's Product Range: Your Trusted Partner

At Enlightening Pallet, we are a leading name in the plastic pallet industry, dedicated to the innovative design and manufacturing of high-quality plastic pallets. Our commitment to excellence ensures that we deliver reliable, recyclable, and eco-friendly solutions to a diverse and global clientele.

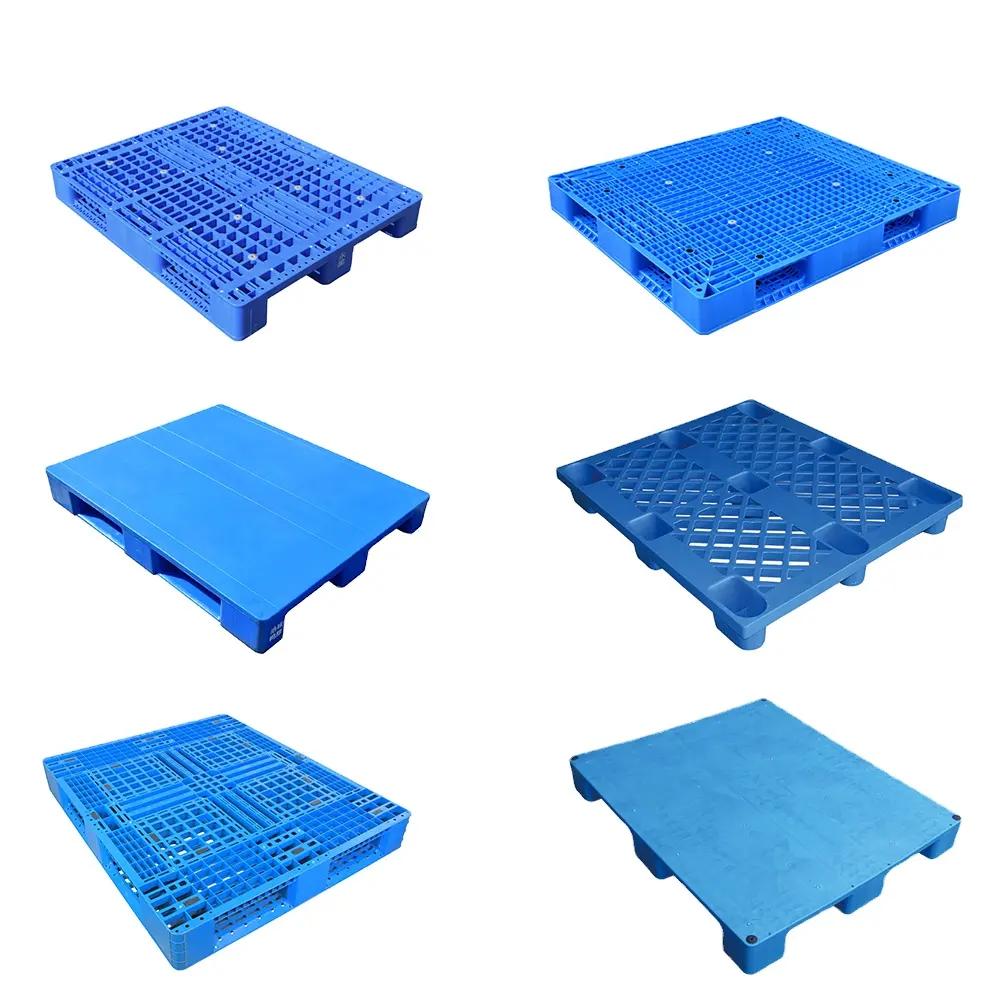

Our portfolio is meticulously structured into five specialized categories, each designed to meet specific industry needs:

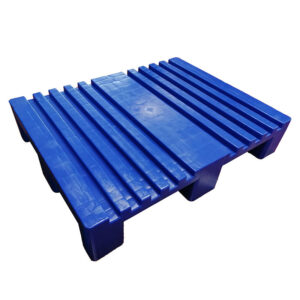

- 9 Legs Plastic Pallet: Perfect for light to medium loads, this pallet provides excellent stability and is ideal for dynamic storage in various logistic operations.

- 3 Skids Plastic Pallet: Designed for heavier loads, these pallets offer enhanced support and durability, suitable for racking and long-term storage.

- Hygienic Plastic Pallet: Specifically engineered for industries that require the highest standards of cleanliness and hygiene, such as food processing and pharmaceuticals.

- Full Perimeter Plastic Pallet: Features a full perimeter base for maximum stability and is ideal for automated handling systems.

- Reversible Plastic Pallet: Versatile and robust, this pallet can be used on both sides, extending its lifecycle and providing greater flexibility for stacking and storage.

-

Ultra-Durable Pallets Designed for Ton Bags

Read more -

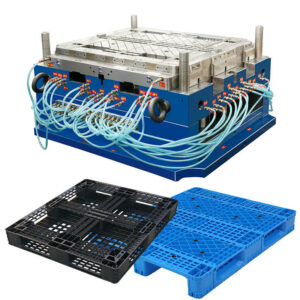

China Industrial Mould Blow Mold Manufacturer For Plastic Pallet

Read more -

New Design Industrial ASRS Plastic Pallet

Read more -

Non-Stop Printing Machine Plastic Palletfor printing machine Hedelberg CD 102

Read more -

1600×1200 HDPE Plastic Pallet for Advanced Storage Solutions

Read more -

4 way one way 9 feets nestable plastic pallet

Read more -

1200*1000mm euro standard size export cargo packaging HDPE plastic pallet

Read more -

9 feet 4 way solid flat top plastic pallets

Read more

At Enlightening Pallet, we specialize in creating custom plastic pallet solutions tailored to meet the unique requirements of your business. Our expertise in customizing pallets ensures that each product is perfectly suited to your specific operational needs, whether for enhanced load capacity, specific dimensions, or specialized features.

Why Opt for Enlightening Pallet’s Custom Plastic Pallets?

- Tailored Design: Each custom plastic pallet is meticulously designed to align with your operational specifics, from overall dimensions to the precise type and placement of reinforcements.

- Advanced Features: We can equip your custom plastic pallets with RFID tags, anti-slip surfaces, or color-coded corners to facilitate easy sorting and identification.

- Material Excellence: Choose from a range of durable materials that best suit your industry needs, ensuring long-lasting performance and compliance with regulatory standards.

- Consultative Expertise: Our team engages in a comprehensive consultation process to deeply understand your challenges and craft solutions that not only meet but exceed your expectations.

Get Your Free Plastic Pallet Catalog Today!

Explore durable, sustainable plastic pallets with competitive plastic pallet prices in our free catalog. Whether for heavy-duty, export, or food-grade applications, find the perfect solution for your logistics needs. Request your free catalog today to access cost-effective, eco-friendly options.

Why Enlightening Pallet is Your Ideal Partner

At Enlightening Pallet, we expertly combine innovation with deep industry experience to deliver superior plastic pallet solutions. Known globally as a trusted partner, we are committed to sustainability, producing eco-friendly, durable, and cost-effective plastic pallets.

Tailored Solutions for Your Business

Recognizing that each client has unique needs, we specialize in custom-made plastic pallets designed to align perfectly with your specific requirements for efficiency, safety, and sustainability. Our approach ensures that when you’re looking to purchase plastic pallets, you receive products that precisely fit your operational needs.

Advanced Manufacturing Technology

Our plastic pallets use cutting-edge production technology to meet the logistics pallet needs of industries such as food, medicine and logistics, making us the choice for those who want to purchase plastic pallets.

Excellent production

Enlightening Pallet has two manufacturing facilities located in Shanghai & Ningbo, With a total area of 90,000-meter square, 60 sets of production lines, and 700 Plastic injection moulds

Competitive, transparent pricing

Our plastic pallets are of premium quality and transparently priced at competitive prices, ensuring you get quality that exceeds value when you decide to purchase plastic pallets from us, no matter the size of your industry.

Connect with Enlightening Pallet!

Comprehensive Guide to Plastic Pallets

Plastic pallets play a crucial role in logistics, not only providing a sturdy platform for goods in transit but also optimizing storage efficiency in warehouses. These pallets are valued for their durability, hygienic design, and adaptability to various environments. Produced by our leading plastic pallet factory, each pallet is manufactured to strict standards, ensuring stability and ease of operation.

These plastic pallets are especially suited for industries that require stringent hygiene controls, such as the food and pharmaceutical industries. Choosing our plastic pallet factory means opting for a partner committed to providing high-quality, reliable, and adaptable plastic pallet solutions, aimed at enhancing your operational efficiency and supporting sustainable business practices.

What is the Plastic Pallet?

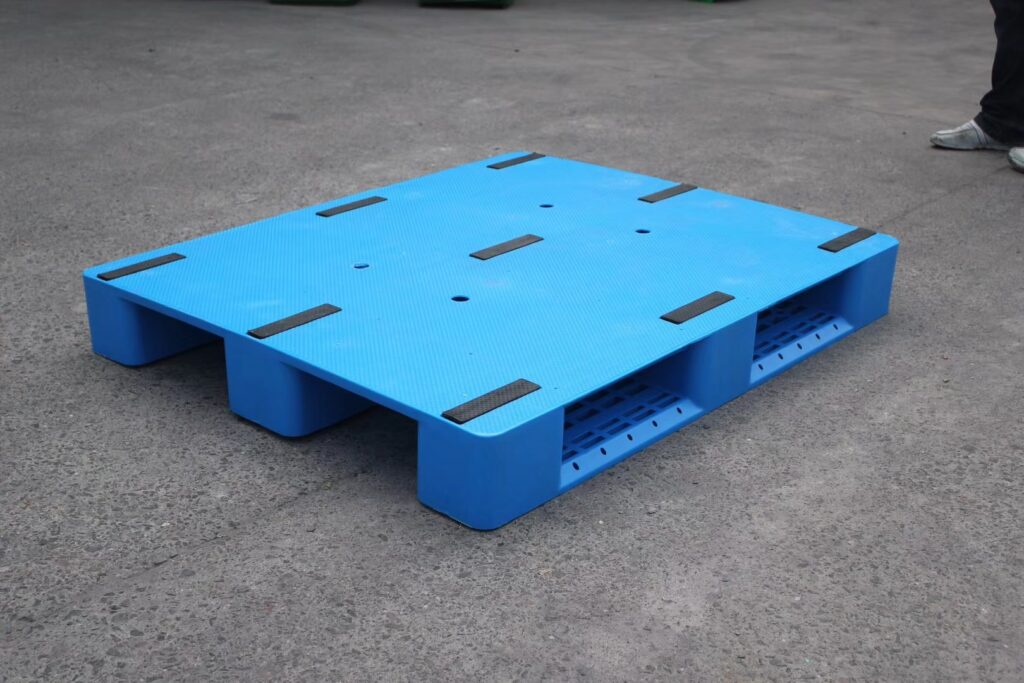

Plastic Pallet is a robust, reusable platform crafted primarily from high-density polyethylene (HDPE) or polypropylene (PP), materials known for their durability and resistance to environmental factors. These pallets are essential in logistics and supply chain operations, facilitating the efficient loading, storing, stacking, and transporting of goods across various industries. Their structural integrity makes them resistant to moisture, impervious to acids, fats, solvents, and odors, and capable of withstanding extreme temperatures. Plastic pallets are also easy to sanitize and are often used in hygienic environments such as food and pharmaceutical production, where cleanliness and contamination prevention are paramount.

Advantages of Plastic Pallets

Plastic pallets offer several distinct advantages across various aspects like lifespan, efficiency, customization, load capacity, environmental impact, and hygiene:

Lifespan: Plastic pallets are known for their durability and long lifespan. Unlike wood pallets that can break or deteriorate quickly due to moisture or pest damage, plastic pallets are made from robust materials such as high-density polyethylene (HDPE) or polypropylene (PP), which can withstand harsh environments and repeated use without significant wear

Efficiency of Use: These pallets are designed for optimal space utilization and can be easily stacked and stored. Their consistent size and shape facilitate automated handling systems, reducing manual labor and increasing operational efficiency

Customization: Plastic pallets can be customized in various ways to meet specific needs. They can be produced in different colors for logistical control, incorporate RFID tags for tracking, and have unique structural designs to handle specific types of loads or fit particular spaces

Load Capacity: They are designed to handle various weights, often better than their wooden counterparts. Heavy-duty plastic pallets, in particular, are engineered to carry substantial loads, making them suitable for a wide range of industrial and commercial applications

Environmental Impact: One of the most significant advantages of plastic pallets is their sustainability. Made from recycled materials, these pallets can be recycled again at the end of their life cycle, reducing the need for new raw materials and minimizing waste

Hygiene: Plastic pallets are non-porous and resist moisture, fats, odors, and chemicals, making them easy to clean and sanitize. This is particularly beneficial in industries requiring stringent hygiene standards, such as food and pharmaceuticals, where preventing contamination is critical

These features make plastic pallets a versatile and eco-friendly option for businesses looking to improve their logistics and sustainability practices.

Custom Guide for Plastic Pallet

When customizing plastic pallets, it’s crucial to consider various specifications to ensure they meet the specific needs of different industries:

1.Durability: These pallets are renowned for their resilience. Made from high-quality materials like HDPE or PP, they resist moisture, chemicals, and physical impacts, making them a long-lasting option. Their robust nature ensures they are a dependable choice for heavy and repeated use in demanding environments.

2.Usage: Plastic pallets are extremely versatile, suitable for use in industries ranging from food and beverage to pharmaceuticals and automotive. Their design can be tailored to facilitate operations, whether it’s for lightweight handling or heavy-duty tasks, enhancing their utility across various sectors.

3.Load Capacity: The strength of these pallets allows them to handle specified weight limits without compromise. Customization options include reinforcing structures to support heavier loads, making them ideal for both light commercial use and heavier industrial applications.

4.Dimensions: Tailoring the dimensions of plastic pallets ensures they fit seamlessly into existing logistics systems, from storage spaces to transport containers. Standard dimensions are commonly optimized for space efficiency and compatibility with handling equipment, facilitating easier and safer operations. This precision in customization allows for the production of industry-specific sizes such as 48×40 and 48×48 plastic pallets, which are prevalent in various supply chain processes, making them ideal for a broad spectrum of commercial and industrial needs.

These customization features help in creating plastic pallets that are not just functional but also aligned with the operational goals and logistical frameworks of businesses, thereby enhancing efficiency and reducing operational costs.

How to Choose the Right Plastic Pallet

1. Determine Your Usage Requirements

- Cold Storage: If your operations involve cold storage, you need a cold storage plastic pallet that can withstand low temperatures without becoming brittle. These pallets are designed to maintain structural integrity in freezing conditions, making them ideal for the food and pharmaceutical industries.

- ASRS Systems: For automated storage and retrieval systems (ASRS) in warehouses, using a Plastic ASRS Pallet for Warehouse is crucial. These pallets are engineered for precision and compatibility with automated handling systems, ensuring smooth operations and reducing downtime.

- Specialized Loads: If you are handling specific products like 5-gallon containers, consider using a 5 Gallon Plastic Pallet. These pallets have the appropriate dimensions and structural support to safely and efficiently transport large, heavy items.

2. Evaluate Load Capacity

- Static and Dynamic Loads: Determine the weight your pallet needs to support when stationary (static load) and when in motion (dynamic load). For heavy-duty applications, choose pallets designed for higher load capacities to prevent damage and ensure safety.

- Racking Loads: If your pallets will be stored in racks, ensure they are designed to handle the rack load without bending or breaking.

3. Assess Durability and Material

- Material Type: High-density polyethylene (HDPE) and polypropylene (PP) are common materials for plastic pallets due to their durability and resistance to chemicals and moisture. Choose the material that best fits your environment and usage conditions.

- Durability Features: Look for features like reinforced corners, steel reinforcements, or additional ribs that enhance the pallet’s durability and lifespan.

4. Size and Design

- Standard Sizes: Depending on your region and industry, standard sizes such as 1200 x 1000 mm, 48×40 inches, and 48×48 inches are common. Ensure the pallet size fits your handling equipment and storage systems.

- Custom Designs: For specialized needs, consider custom-designed pallets that cater to your specific product dimensions and operational workflows. Custom plastic pallets can provide enhanced efficiency and safety in your logistics processes.

5. Environmental Considerations

- Sustainability: Opt for pallets made from recycled materials if environmental sustainability is a priority for your business. Many plastic pallet suppliers offer eco-friendly options that do not compromise on quality or performance.

Manufacturing Process of Plastic Pallets

The manufacturing of plastic pallets primarily involves two major techniques: Injection Molding and Rotational Molding. Each method has its unique advantages and applications. Below, we outline these processes and highlight how they cater to different needs, including products like HDPE Material Euro Plastic Pallets, Warehouse Storage Euro Plastic Pallets with Steel Reinforce, and Recycled HDPE Plastic Pallet.

Injection Molding

Injection molding is a widely used method for producing high-performance plastic pallets. This process involves several key steps:

- Material Preparation: High-density polyethylene (HDPE) or polypropylene (PP) pellets are melted and mixed with colorants and any other additives.

- Injection: The molten plastic is injected into a mold under high pressure. This mold is designed to form the pallet’s exact shape and dimensions.

- Cooling: Once injected, the mold is cooled, allowing the plastic to harden and take shape.

- Ejection: The finished pallet is ejected from the mold, ready for any final processing steps, such as trimming or adding reinforcements.

Advantages:

- Precision and Strength: Injection molding allows for high precision and strength, making it ideal for producing durable pallets like HDPE Material Euro Plastic Pallets.

- High Volume Production: This method is suitable for large-scale production runs, ensuring consistency across thousands of pallets (Wee Pallet) (Go4Mould).

Rotational Molding

Rotational molding, or rotomolding, is another technique used to manufacture plastic pallets, particularly when producing complex shapes or hollow parts.

- Material Loading: A pre-measured amount of powdered plastic resin is placed into a mold.

- Heating and Rotation: The mold is heated while being rotated along two perpendicular axes. This ensures even distribution of the melted plastic along the interior surfaces of the mold.

- Cooling: The mold continues to rotate while cooling, allowing the plastic to solidify evenly.

- De-molding: The mold is opened, and the finished pallet is removed.

Advantages:

- Complex Shapes: Rotational molding is ideal for producing pallets with complex shapes and hollow structures.

- Cost-Effective for Small Batches: This method is more cost-effective for producing smaller batches of custom pallets, such as Warehouse Storage Euro Plastic Pallets with Steel Reinforce (Plastic Pallet Pros) (One Way Solutions).

Comparison and Applications

- Injection Molding is preferred for high-volume production and applications requiring high strength and precision. It’s ideal for standard-sized pallets used in heavy-duty and export applications.

- Rotational Molding is suited for creating complex, customized designs, including pallets that need to integrate special features or reinforcements. It’s beneficial for producing pallets in smaller quantities where flexibility in design is crucial.

Material Selection for Plastic Pallets

Selecting the appropriate material for plastic pallets is crucial for ensuring they meet the performance and durability requirements of various applications. Here’s a concise guide on material selection, tailored to different market needs and including our specific products.

High-Density Polyethylene (HDPE)

HDPE is widely used for its exceptional properties:

Durability and Strength: HDPE is highly durable and resistant to impact and chemicals, making it ideal for heavy-duty applications such as HDPE Material Euro Plastic Pallets.

Recyclability: This material is commonly recycled, which supports the production of Recycled HDPE Plastic Pallet and promotes sustainability

Polypropylene (PP)

PP offers several advantages:

Rigidity and Strength: PP is more rigid than HDPE, providing excellent support for heavy loads. It is suitable for a variety of industrial uses.

Chemical Resistance: PP is durable in harsh environments, making it a cost-effective choice for disposable plastic pallets

Structural Foam

Structural Foam enhances the strength and stability of plastic pallets:

Lightweight and Strong: This material is used in applications requiring additional support without significant weight, such as Warehouse Storage Euro Plastic Pallets with Steel Reinforce. The structural foam molding process creates a robust yet lightweight pallet .

Fiberglass

Fiberglass is selected for its unique properties:

High Strength and Fire Resistance: Fiberglass is extremely durable and naturally fire-retardant, making it suitable for specialized applications in industries like automotive and aerospace. However, it is more expensive and less commonly used compared to other materials .

Recycled Plastics

Using Recycled Plastics is essential for eco-friendly pallet production:

Environmental Impact: Recycled plastics help reduce waste and the carbon footprint of pallet manufacturing. This material retains many of the beneficial properties of virgin plastics, making it suitable for producing cost-effective and sustainable pallets.

Each material has its unique benefits, making them suitable for specific industrial requirements. By understanding the properties and applications of these materials, businesses can select the most appropriate type of plastic pallet to enhance their logistics and operational efficiency.

Why Choose Enlightening Pallet for Your Plastic Pallet Needs?

Enlightening Pallet distinguishes itself by expertly crafting 9 Legs Plastic Pallets to meet your specific requirements. We excel in transforming high-quality materials like HDPE, PP, and fiberglass into various pallet forms, ensuring they align with your unique demands.

Our experienced team works closely with you to customize solutions, focusing on your specifications. Through partnerships with leading manufacturers, we guarantee top-tier plastic pallets.

Selecting Enlightening Pallet means choosing more than just a product; it’s a commitment to excellence. You’re assured of receiving plastic pallets that are not only high in quality and durability but also embody our dedication to sustainability and customer satisfaction.

Precautions for Handling and Use of Plastic Pallets

Plastic pallets offer numerous advantages, including durability, resistance to moisture and chemicals, and ease of handling. However, to maximize their lifespan and ensure safety, it’s important to follow certain precautions during their handling and use. Here are some key precautions to consider:

1. Proper Loading and Weight Distribution

- Weight Limits: Always adhere to the recommended weight limits specified by the pallet manufacturer. Overloading can cause the pallets to deform or break, leading to potential safety hazards.

- Even Distribution: Ensure that the load is evenly distributed across the pallet. Uneven loading can cause the pallet to tip or become unstable, increasing the risk of accidents during transport and storage .

2. Safe Handling Practices

- Forklift Use: When using forklifts, make sure the forks are fully inserted into the pallet openings to provide stable lifting. Avoid tilting the forks, which can damage the pallet or cause it to slip.

- Manual Handling: If manually handling the pallets, always lift with proper techniques to avoid injury. Bend your knees, keep your back straight, and use the strength of your legs to lift .

3. Storage Considerations

- Stacking: When stacking plastic pallets, do not exceed the recommended stacking height. Over-stacking can lead to instability and potential collapse. Additionally, ensure that the stacked pallets are on a flat, stable surface.

- Temperature and Environment: Store pallets in environments that do not exceed the material’s temperature limits. Extreme temperatures, particularly high heat, can affect the integrity of the plastic, causing it to warp or become brittle .

4. Regular Inspections and Maintenance

- Routine Checks: Regularly inspect the pallets for signs of damage such as cracks, warping, or significant wear. Damaged pallets should be repaired or replaced promptly to prevent accidents.

- Cleaning: Clean the pallets regularly to remove debris and contaminants that could compromise their performance. Use appropriate cleaning agents that do not degrade the plastic material.

By adhering to these precautions, you can ensure that your plastic pallets provide reliable, long-term service while maintaining safety in your operations.

Cleaning and Maintenance of Plastic Pallets

Proper cleaning and maintenance of plastic pallets are essential to ensure their longevity and performance. Here are some guidelines to help you keep your plastic pallets in optimal condition:

1. Regular Cleaning

- Debris Removal: Routinely remove any debris, dirt, or residues from the pallets. This can be done using a brush or compressed air to ensure all particles are cleared away.

- Washing: Use water and mild detergents to wash the pallets. High-pressure washers can be effective in removing stubborn dirt and grime. Ensure the detergent used is suitable for plastic and does not cause degradation

2. Disinfection

- Sanitizing Solutions: For pallets used in sensitive environments such as food or pharmaceuticals, it is important to sanitize them regularly. Use appropriate sanitizing solutions that are effective against bacteria and viruses but safe for plastic materials.

- Rinsing: After applying disinfectants, thoroughly rinse the pallets with clean water to remove any chemical residues that might affect the products being transported or stored

- Routine Checks: Conduct regular inspections to check for any signs of damage, such as cracks, warping, or wear. Inspect both the surface and structural integrity of the pallets to ensure they are safe to use.

- Repairs: If any damage is found, assess whether the pallet can be repaired or needs to be replaced. Minor cracks can sometimes be fixed, but severely damaged pallets should be taken out of circulation to prevent accidents

4. Storage

- Proper Storage Conditions: Store pallets in a dry, well-ventilated area to prevent mold and mildew growth. Avoid exposing pallets to extreme temperatures, which can cause them to warp or become brittle.

- Stacking: When not in use, stack pallets properly to avoid any deformation. Ensure that the stacking height does not exceed the recommended limit to maintain stability and prevent accidents

5. Handling

- Correct Handling Practices: Ensure that the pallets are handled properly to avoid unnecessary damage. Use forklifts or pallet jacks as intended, and make sure the forks are fully inserted to prevent cracking or breaking of the pallet structure.

- Avoid Overloading: Adhere to the weight limits specified by the manufacturer. Overloading pallets can lead to structural damage and reduce their lifespan

By following these cleaning and maintenance guidelines, you can extend the life of your plastic pallets and ensure they remain safe and effective for your logistical needs.

Choosing the Right Plastic Pallets Manufacturer or Supplier

Selecting an appropriate manufacturer or supplier for plastic pallets involves several key considerations:

- Industry Certifications: Look for certifications like ISO9001 to ensure quality and regulatory compliance.

- Product Range: Choose suppliers offering diverse pallet types, indicating expertise and ability to meet various needs.

- After-sales Support: Prioritize suppliers providing robust after-sales service for long-term satisfaction.

- Safety Standards: Ensure they comply with safety regulations and industry standards.

- Reputation and Reviews: Assess their reliability through customer feedback and references.

- Technical Expertise: Evaluate their knowledge to help select suitable pallets for your needs.

- Customization Options: Check if they offer customization for specific requirements.

- Transparent Pricing and Communication: Opt for suppliers with clear pricing and effective communication to avoid hidden costs.

Get In Touch With Us

Our Product Range

Innovative Solutions Exceptional Support

Elevate your business with our streamlined and advanced solutions. Join hands with Enlightening Plast for a future of innovation and reliability.

Precision Engineering

Our plastic product, crafted by Professional Experts, offer unmatched protection with a 360-degree approach.

Technological Excellence

Stay ahead with our Technology & Innovations integrated into every product for cutting-edge solutions.

Dedicated Assistance

Experience peace of mind with Premium Support that caters to your needs, ensuring a seamless partnership.